In the fast-evolving world of manufacturing and construction, securing a dependable wire supply is increasingly essential for businesses aiming to enhance productivity and streamline operations. As the industry undergoes constant innovation, understanding the nuances of wire supply solutions can significantly affect a company's bottom line. Renowned wire supply expert, Dr. John Thompson, emphasizes this point, stating, "A robust and efficient wire supply chain is the backbone of any successful manufacturing operation."

In our 2025 guide, we will explore various strategies and best practices to optimize your wire supply, addressing the critical elements such as sourcing, inventory management, and vendor relationships. With rising material costs and fluctuating market demands, businesses must adapt their wire supply solutions to maintain competitiveness and ensure operational resilience. By focusing on holistic approaches that encompass both technical specifications and logistical efficiencies, organizations can better position themselves to meet upcoming challenges in the industry.

As we delve into this guide, we will provide insights that help you navigate the complexities of wire supply, thereby empowering your business to thrive in an increasingly competitive landscape. Whether you're a small enterprise or a large corporation, understanding the principles of efficient wire supply management is vital for sustainable growth and operational excellence in the years ahead.

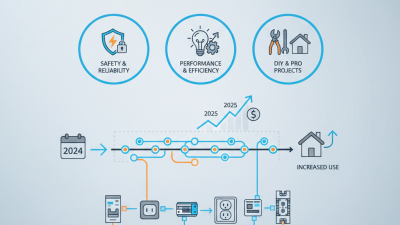

As industries evolve in 2025, the wire supply solutions landscape is experiencing significant transformations to meet diverse operational needs. One prominent trend is the increasing shift towards sustainable and eco-friendly materials. Many businesses are now prioritizing suppliers that offer wires made from recycled or biodegradable materials, aligning with the global push for sustainability. This shift not only helps companies reduce their carbon footprint but also enhances their brand reputation as environmentally responsible entities.

Another key trend is the integration of technology into wire supply chains. The advent of smart manufacturing and the Internet of Things (IoT) is driving companies to adopt more advanced inventory management systems. These advanced systems utilize real-time data to forecast demand accurately, ensuring that businesses maintain optimal stock levels without overextending resources. Enhanced communication tools also facilitate better collaboration between suppliers and manufacturers, allowing for more efficient problem-solving and quicker response times to market changes.

Additionally, the diversification of industries adopting wire solutions cannot be overlooked. Sectors such as renewable energy, automotive, and telecommunications are increasingly relying on high-performance wire products to support their innovations. As these industries advance, they require tailored wire supply solutions that offer enhanced durability, conductivity, and flexibility. Therefore, suppliers are more inclined to develop specialized products that cater to the unique requirements of each sector, fostering a more resilient and adaptive supply chain landscape.

Assessing wire supply needs is critical for businesses of all sizes, especially as industries evolve and adopt new technologies. According to the 2023 Wire Industry Report, approximately 60% of businesses fail to accurately forecast their wire supply needs, leading to inefficiencies and increased costs. Utilizing key metrics such as production volume, project timelines, and inventory turnover rates can help enterprises establish a more effective procurement strategy tailored to their specific scale.

For small businesses, a lean approach is essential. Maintaining a lower inventory level—around 15% of projected annual needs—can mitigate holding costs while ensuring enough supply for immediate production demands. Conversely, larger enterprises might benefit from a more comprehensive inventory management system, where a 30% buffer can safeguard against supply chain disruptions. By regularly analyzing production data and adjusting wire supply accordingly, companies can avoid excess stock that ties up capital.

Tips: Embrace technology by implementing software solutions designed for supply chain management. Real-time data can enhance visibility into inventory levels and procurement processes, leading to more informed decision-making. Additionally, conducting regular assessments of supplier performance and exploring alternative sourcing options can enhance flexibility and responsiveness to market changes. These practices can lead to better resource allocation, which is essential for both small and large-scale operations.

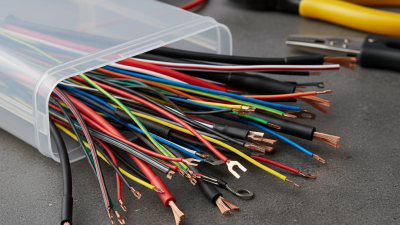

In today's competitive market, efficient wire supply management is essential for businesses aiming to optimize their operations while controlling costs. Conducting a thorough cost analysis is pivotal in budgeting for wire supply needs. This involves assessing both direct and indirect costs related to sourcing, storing, and utilizing wire materials. Direct costs include the purchase price of wires and shipping expenses, while indirect costs might encompass inventory holding costs and potential waste due to inefficiencies in supply chain practices.

Businesses should adopt a strategic approach to budgeting that includes forecasting future wire supply requirements based on production schedules and market demand. By implementing just-in-time inventory systems, companies can reduce excess stock while minimizing storage costs. It is also beneficial to analyze historical data to identify usage patterns, thereby informing more accurate predictions and reducing the risk of over-ordering or stockouts. Engaging with multiple suppliers can further help in negotiating better prices, ensuring that the budget aligns with the overall financial health of the business while maintaining a reliable supply line.

Sustainability has become a pivotal concern within the wire supply industry, particularly as businesses strive to minimize their environmental impact. Recent data from a report by the Global Sustainable Wire Association indicates that over 60% of manufacturers are now incorporating eco-friendly materials into their production processes. This shift is driven by both regulatory pressures and consumer demand for greener products, allowing businesses to enhance their sustainability profiles while reducing costs associated with waste and energy consumption.

One prominent eco-friendly option is the use of recycled metals, which can significantly lower the carbon footprint associated with wire production. According to the International Recycling Bureau, recycling aluminum and copper can reduce energy consumption by up to 95% compared to traditional extraction methods. Additionally, innovative practices such as utilizing bioplastics in insulation materials are gaining traction, offering similar performance qualities as their petroleum-based counterparts, but with reduced environmental impacts. Businesses that adopt these sustainable practices not only contribute to a healthier planet but also position themselves favorably in an increasingly conscientious marketplace, where consumers are willing to pay a premium for eco-friendly options.

In today's rapidly evolving business landscape, technological advancements play a crucial role in enhancing efficiency within wire supply chains. Innovations such as automated inventory management systems have transformed the way businesses track and manage their wire supplies. By leveraging real-time data analytics, companies can forecast demand more accurately, minimize overstocking and understocking issues, thereby reducing operational costs and improving service levels.

Additionally, the integration of smart technologies such as the Internet of Things (IoT) and blockchain has significantly streamlined processes within the supply chain. IoT devices enable companies to monitor equipment in real-time, ensuring that potential issues are addressed before they escalate into costly delays. Blockchain technology enhances transparency and traceability, allowing stakeholders to verify the movement of materials throughout the supply chain.

With these innovations, businesses can achieve unprecedented levels of operational efficiency and reliability, setting the stage for sustained growth and competitive advantage in the wire supply market.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.