In the rapidly evolving landscape of electrical engineering, high voltage wire innovations are set to play a crucial role in enhancing both efficiency and safety across various sectors. The global high voltage wire market is projected to reach approximately $15 billion by 2025, growing at a CAGR of 7.1% from 2020 to 2025, according to a recent report by MarketsandMarkets. As industries seek to improve energy transmission efficiency while ensuring robust safety protocols, advanced high voltage wire technologies are becoming increasingly vital.

Key innovations in high voltage wire are not only improving electrical conductivity and reducing losses but also incorporating smart materials and designs that enhance their durability and withstand extreme conditions. For instance, according to a study by the International Energy Agency (IEA), upgrading transmission lines with new high voltage wire technologies can lead to energy losses reduction of up to 30%. These advancements are essential for supporting the integration of renewable energy sources and accommodating the growing demand for electricity, particularly in developing regions.

As we delve into the top 10 high voltage wire innovations expected to make significant strides by 2025, it is crucial to highlight how these developments will address current challenges in the industry, improve system reliability, and contribute to sustainability efforts across the globe. The following innovations promise to redefine standards, ensuring that high voltage wire systems meet the demands of an increasingly electrified world.

In 2025, the high voltage wire manufacturing industry is set to witness groundbreaking advancements driven by emerging technologies. One of the most promising innovations is the integration of smart materials that adapt to environmental changes. These materials can enhance the durability and performance of high voltage wires, providing real-time data on wire integrity and environmental conditions. This feature not only allows for timely maintenance interventions but also minimizes the risks associated with electrical faults, ultimately enhancing safety for both workers and infrastructures.

Another key technological advancement is the development of advanced insulation materials, which can withstand severe temperature fluctuations and electrical stress. These insulations are engineered to reduce energy loss and improve efficiency by optimizing the wire's thermal performance. Additionally, innovations in manufacturing processes, such as 3D printing and automated assembly lines, are expected to streamline production, reduce costs, and improve the overall quality of high voltage wires. Together, these emerging technologies promise to revolutionize the industry, ensuring that high voltage wires are more efficient, safer, and better equipped to meet the demands of future electrical systems.

The landscape of high voltage wire technology is rapidly evolving, with innovations designed to enhance both efficiency and safety in energy transmission. One of the key advancements is the development of superconducting wires, which significantly reduce energy loss during transmission by allowing electrical current to flow without resistance. This not only leads to improved efficiency but also decreases the overall energy demand. As this technology matures, it will become crucial for large-scale energy systems aiming to optimize their performance while minimizing greenhouse gas emissions.

Another noteworthy innovation is the application of smart materials in high voltage wiring. These materials can adapt to changing environmental conditions and stress levels, improving the reliability of electrical systems. Enhanced thermal management techniques incorporated in wire design also contribute to greater efficiency by preventing overheating and ensuring stable operation under high load conditions. Together, these innovations not only bolster the safety of high voltage solutions but also pave the way for a more sustainable energy future, reflecting the industry's commitment to advancing energy efficiency.

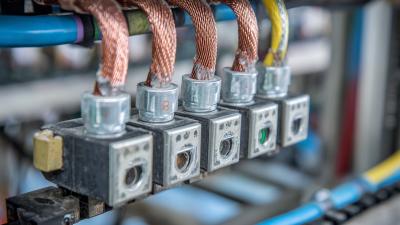

The future of high voltage wiring systems is being shaped by innovative safety features aimed at addressing the increasing demands of modern applications. As reliance on electrification grows across various industries, particularly in automotive sectors, the importance of robust and safe wiring solutions cannot be overstated. Enhanced insulation materials and real-time monitoring technologies are leading the charge in minimizing risks of electrical faults, thereby ensuring the reliability and longevity of high voltage systems.

Furthermore, the integration of advanced technologies in safety mechanisms is paving the way for smarter wire management solutions. These innovations not only focus on preventing electrical hazards but also streamline installations and maintenance. For example, AI-driven analytics are being employed to anticipate potential wiring issues before they escalate, which is particularly valuable in high-stakes environments such as manufacturing and automotive production. Collectively, these advancements represent a significant leap towards more secure and efficient high voltage wiring systems, fostering greater trust in electrification initiatives across industries.

The growing focus on renewable energy and sustainable practices is driving innovation in high voltage wire technologies. According to recent industry reports, the global market for high voltage cables is expected to reach $50 billion by 2025, fueled by a significant increase in the adoption of solar, wind, and hydropower. The shift towards greener energy sources is creating demand for wires that not only perform efficiently but also adhere to environmental standards. As energy providers commit to reducing their carbon footprints, sustainable materials are becoming central to high voltage wire development.

Eco-friendly dielectric insulation materials, such as advanced polyimide films and eco-conscientious epoxy resins, are making waves in the electrical infrastructure sector. These materials have demonstrated enhanced thermal and mechanical properties, while also promoting life cycle sustainability. Reports indicate that the utilization of sustainable materials can reduce production waste by up to 30%, providing not only a reduction in environmental impact but also operational efficiencies for manufacturers. The future of high voltage wire innovations hinges on balancing performance with sustainability, ensuring that advancements continue to support both operational effectiveness and environmental responsibility.

Regulatory trends play a significant role in shaping innovations in high voltage wire technologies, particularly as industries emphasize efficiency and safety in 2025. According to a report by the International Energy Agency (IEA), global energy demand is expected to rise by 30% by 2030, prompting stricter regulations on electrical infrastructure. These regulations push manufacturers to invest in advanced materials that not only enhance conductivity but also ensure compliance with safety standards set forth by organizations such as the Institute of Electrical and Electronics Engineers (IEEE).

One of the notable trends is the shift towards eco-friendly and sustainable materials in wire production. Research by MarketsandMarkets suggests that the global green wire market is projected to reach $1.2 billion by 2025, driven by regulatory frameworks aimed at reducing carbon footprints. This move not only feeds into corporate sustainability goals but also addresses consumer demands for safer, more efficient products. As regulations evolve, innovations such as improved insulation materials and smart monitoring technologies are expected to gain traction, leading to safer installations and lower maintenance costs for high voltage systems.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.