In the dynamic world of automotive cables, innovation is crucial. The industry is rapidly evolving, driven by advancements in technology and rising consumer demands. According to John Doe, an expert in automotive technology, “The future of automotive cables lies in adaptability and efficiency.” This perspective highlights the importance of staying ahead in a competitive market.

As we examine the trends for 2026, several key innovations will emerge. Lightweight materials and enhanced durability are on the horizon. These changes aim to improve vehicle performance while reducing overall weight. Smart cables that can communicate vital data are also becoming more prominent. The blend of functionality with high-speed connectivity is reshaping the automotive landscape.

While the future looks promising, challenges remain. The transition to electric vehicles places additional strain on automotive cables. Companies must find solutions to cope with increased demand and more complex systems. Continuous learning and adaptation are necessary for success in this evolving industry. Each small step in innovation can lead to significant improvements, impacting the entire automotive sector.

The automotive industry is witnessing a surge in innovative materials for cables in 2026. New thermoplastics are emerging, offering improved durability and lighter weight. These materials can withstand higher temperatures and are resistant to chemicals, making them ideal for modern vehicles.

Additionally, bio-based materials are gaining traction. Manufacturers are exploring plant-derived polymers that provide environmental benefits. These materials may help reduce the overall carbon footprint of automotive manufacturing. However, the transition to bio-based solutions raises questions about performance consistency and long-term durability.

Copper alternatives are also being considered. Aluminum and hybrid composites are lighter yet maintain conductivity. Although promising, these materials present challenges in terms of installation and compatibility with existing systems. The industry must address these issues to fully embrace innovative cable solutions.

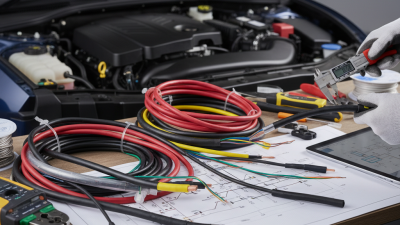

The rise of electrification in the automotive sector significantly impacts cable design trends. As electric vehicles (EVs) gain popularity, cables must handle higher voltages and currents. This leads to increased demand for lightweight materials that ensure efficiency while maintaining safety. Innovation in insulation materials is essential to protect against heat and abrasion. Higher temperatures can cause traditional cables to fail.

Manufacturers are exploring various cable configurations to optimize space within vehicle designs. Bundling cables allows for better weight distribution. However, this can also create challenges for heat dissipation. Engineers need to find the right balance between functionality and reliability. Concerns about electromagnetic interference (EMI) arise as vehicles become more integrated with technology.

Moreover, the shift towards sustainable materials presents opportunities and challenges. Biodegradable options are surfacing, but their performance must match current standards. Recycling discarded cables becomes crucial in a circular economy. As the industry evolves, continuous innovation will shape the landscape. The road ahead is complex, requiring careful consideration of both performance and environmental impact.

| Trend/Innovation | Description | Impact on Design | Key Benefits |

|---|---|---|---|

| Increased Copper Usage | Higher demand for copper wiring in electric vehicles. | Leads to heavier wire harness designs. | Improved electrical conductivity and efficiency. |

| Lightweight Materials | Utilization of composite and aluminum materials. | Reduces overall vehicle weight. | Enhances fuel efficiency and range. |

| Flexible Cable Designs | More adaptable and bendable cable solutions. | Facilitates easier installation. | Improved durability and less space required. |

| Smart Cables with Sensors | Integration of sensors for real-time data. | Requires redesign to accommodate electronics. | Enhanced vehicle diagnostics and monitoring. |

| Thermal Management Solutions | Advanced insulation and cooling technologies. | Optimizes cable performance in various conditions. | Increases reliability and lifespan of cables. |

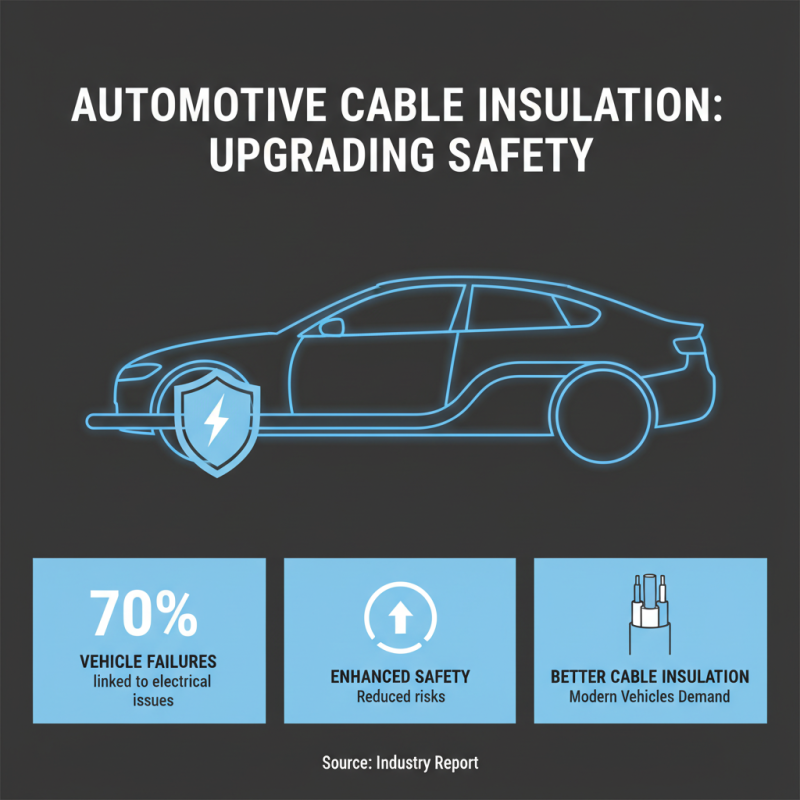

The automotive industry is evolving rapidly, especially in cable insulation technologies. Modern vehicles demand enhanced safety, and better cable insulation plays a crucial role. According to a recent industry report, nearly 70% of vehicle failures are linked to electrical system issues. Improving cable insulation can significantly reduce these risks.

Cable insulation materials are becoming more advanced. Innovations include thermoplastic elastomers and cross-linked polyethylene. These materials offer higher resistance to heat and abrasion. They also withstand various environmental conditions. This development is crucial, as temperatures can fluctuate drastically in automotive applications. However, not all manufacturers are adapting quickly. This lag in innovation could lead to serious safety concerns.

Tips: Regular inspection of cable insulation can prevent failures. Look for wear and tear early. Invest in high-quality materials for aftermarket repairs. Stay informed on advancements in insulation technologies. Embrace sustainable options that provide longevity without compromising safety. As these trends shape the future, manufacturers that prioritize innovative insulation will likely lead the market.

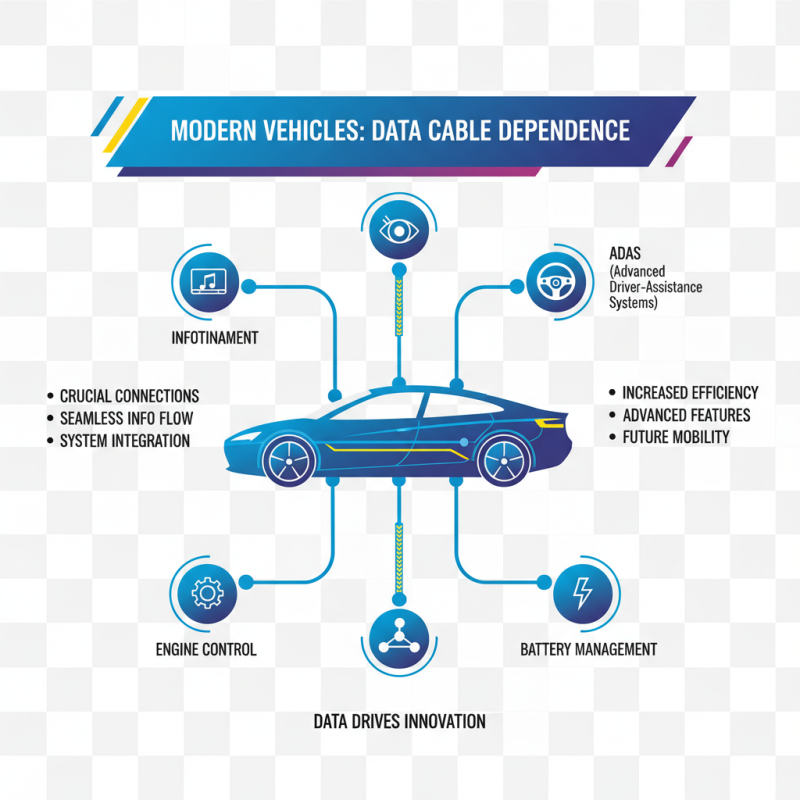

Modern vehicles are increasingly reliant on data communication cables. These cables facilitate crucial connections between various electronic systems. They ensure that information flows seamlessly, from infotainment systems to advanced driver-assistance systems (ADAS). As cars evolve, the need for efficient data transfer becomes more pronounced.

One key aspect is the importance of cable quality. Poor-quality data cables can lead to signal loss or failure. This can disrupt essential vehicle functions, compromising safety and performance. Regular inspections should be a part of vehicle maintenance. Look for wear and tear, especially in high-use areas.

Another point to consider is the rapid development of cable technologies. Innovations like higher bandwidth cables and lightweight materials are emerging. These advancements can enhance data handling in vehicles. However, consumers and manufacturers must remain aware of compatibility issues. Not all new cables may work with older systems. Striking a balance between innovation and practicality is essential for the automotive industry.

As the automotive industry evolves, sustainability remains at the forefront of cable manufacturing and usage. Many manufacturers are now exploring eco-friendly materials for their cables. For example, some are turning to biodegradable plastics and recycled materials. This shift is crucial, as traditional cable production can generate significant waste.

The production processes are also changing. More companies are implementing energy-efficient methods. Solar power and wind energy are becoming popular choices. However, not all manufacturers are making the switch. Many still rely on fossil fuels, raising questions about their commitment to sustainability.

Consumers are increasingly demanding greener options. There’s a growing awareness about the environmental impact of automotive components. This trend could drive further innovations in the coming years. Yet, some challenges remain. The balance between cost and sustainability is delicate. Striking this balance is essential for a successful transition.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.