High temperature cables are essential in various industries. They are designed to withstand extreme conditions. These cables ensure reliable performance in high-heat environments.

In 2026, the demand for high temperature cable is expected to grow. Industries such as aerospace and automotive rely heavily on them. These cables can endure high levels of heat without losing functionality. However, not all high temperature cables are created equal. Some may struggle under specific conditions.

Understanding the various uses and benefits of high temperature cables is crucial. They offer durability and resilience in challenging environments. Yet, it’s vital to consider the limitations and potential failures. These challenges can impact operational efficiency. Adapting to new materials and technologies can help overcome these issues.

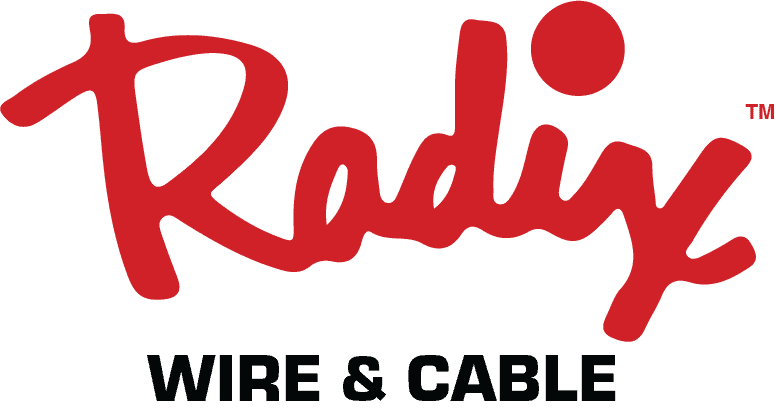

High temperature cables play a crucial role in various industrial applications. Their ability to resist extreme heat makes them essential in sectors like aerospace, automotive, and manufacturing. These cables are designed to function reliably in environments where traditional cables might fail. The materials used provide insulation and durability, even under significant thermal stress.

These cables often operate in conditions exceeding 200 degrees Celsius. In power plants, for instance, they connect critical equipment requiring high reliability. If a cable fails, it can lead to severe operational disruptions. Yet, not all high temperature cables are created equal. Some may not withstand specific thermal challenges. This inconsistency can raise concerns among engineers and decision-makers.

When selecting high temperature cables, it's vital to consider application specifics. Factors like thermal conductivity, flexibility, and installation conditions must be evaluated. There’s always room for improvement. For instance, enhancing the clarity of specifications can help avoid misunderstandings during installation. A deeper understanding of each use case can drive better choices in materials and designs.

High temperature cables find vital applications across various industries. They excel in environments where normal cables fail. Industries like aerospace, automotive, and oil and gas depend on these robust solutions. For instance, in aerospace, high temperature cables can withstand extreme thermal exposure. They ensure safety and performance in flight operations. Similarly, the automotive sector requires these cables for components near engines.

In the oil and gas industry, cables endure intense heat while powering critical systems. They play a pivotal role in exploration and extraction operations. High temperature cables also contribute to renewable energy projects. Solar and wind energy installations rely on them for efficiency and safety.

Tip: Always check the temperature rating. Not all high temperature cables have the same capabilities.

Consider installation practices carefully. Poor installation can lead to failures, even with quality cables. Ensure that your team is trained well. Using the right accessories can enhance the performance of these cables.

Tip: Consult with experts during the planning phase. They can provide insights into the specific requirements of your project.

| Application Industry | Cable Type | Temperature Rating (°C) | Main Benefits |

|---|---|---|---|

| Aerospace | Silicone Rubber | 200 | Lightweight, Flexible, High Performance |

| Automotive | PTFE | 260 | Chemical Resistant, Durable, Low Friction |

| Industrial Equipment | Fiberglass Insulated | 300 | High Thermal Stability, Resistant to Occupational Hazards |

| Oil & Gas | EPR | 150 | Excellent Insulation, Moisture Resistant |

| Renewable Energy | XLPE | 90 | UV Resistant, Long Life Span |

High temperature cables are essential for many industries. They can operate effectively in extreme environments. These cables are often used in power generation, aerospace, and manufacturing sectors. According to a recent industry report, high temperature cables can endure temperatures up to 250°C and more. This makes them ideal for energy-efficient operations.

Benefits of using high temperature cables include improved energy efficiency. They minimize energy loss during transmission. Research indicates that using these cables can enhance system performance by up to 20%. This leads to reduced operational costs. High temperature cables also have a longer lifespan, which reduces the need for frequent replacements.

Tip: For installations, ensure the correct cable type is selected based on specific temperature ratings.

Another point of consideration is the initial cost. High temperature cables may be more expensive upfront. However, their durability and efficiency can lead to savings over time. Choosing the right cable can seem challenging. However, the benefits often outweigh the drawbacks.

Tip: Consult with industry professionals to evaluate your project needs.

High temperature cables are crucial in various industries. They must withstand extreme conditions without losing functionality. The materials used in their manufacturing significantly impact performance and durability. Common materials include silicone, fluoropolymers, and ceramic insulation. Each offers unique advantages, such as resistance to heat, chemicals, and abrasion.

Silicone is flexible and maintains performance at high temperatures. It can resist temperatures up to 300°C. Fluoropolymers offer excellent electrical insulation and chemical resistance. Their temperature resistance can reach over 200°C. Ceramic materials provide exceptional thermal stability but can be brittle. Choosing the right material depends on the application requirements.

It's vital to consider the specific environment. Not all materials perform equally in all situations. For instance, while silicone is great for flexibility, it might not be the best in highly corrosive environments. Therefore, a thorough assessment is necessary to ensure optimal cable performance. This analysis not only helps in selecting materials but also in anticipating possible failures. Understanding the properties of each material can lead to better decision-making.

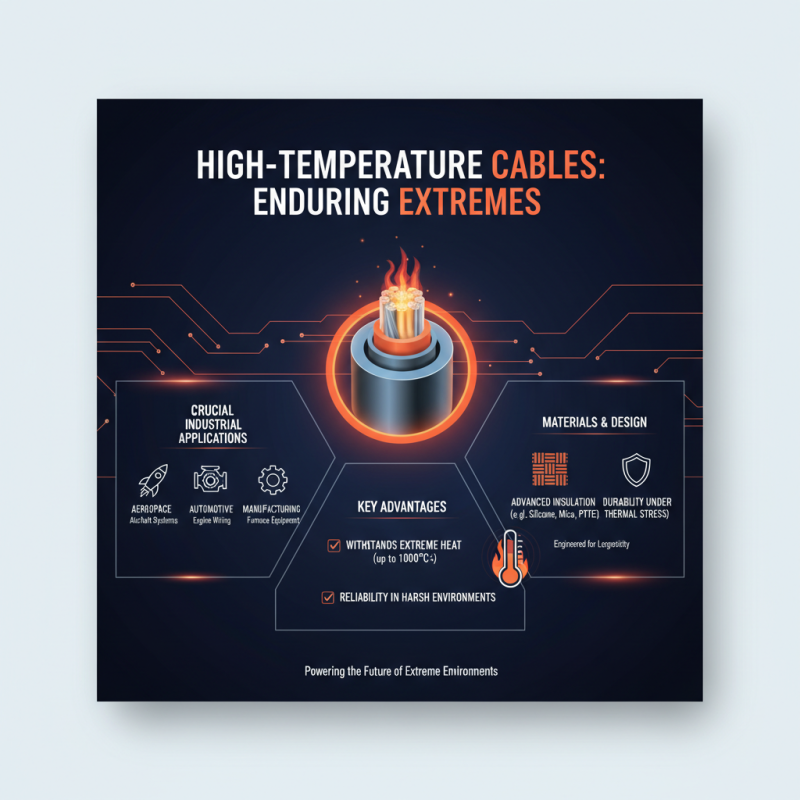

High temperature cable technology is rapidly evolving. As industries require more durable and efficient solutions, innovation has taken center stage. The future of high temperature cables is promising, with advancements in materials and manufacturing processes. These innovations will enhance the performance of cables under extreme conditions.

One significant trend is the development of new insulation materials that withstand higher temperatures. This change allows for greater flexibility in application. Cables can be used in environments such as aerospace, automotive, and industrial manufacturing. Another focus is improving the thermal conductivity of these cables. Enhanced conductivity can reduce energy loss, making systems more efficient.

However, challenges remain. Production costs for advanced materials can be high. This may slow widespread adoption. There are also concerns regarding long-term reliability. Companies must invest in testing and quality assurance to ensure these cables perform as expected over time. It’s crucial to balance innovation with practical applications to truly benefit the industry.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.