In the realm of high-temperature applications, the selection of the right high heat wire is crucial for ensuring performance and safety. According to Dr. Emily Carter, a renowned expert in thermal materials, “The choice of high heat wire can significantly impact not only the efficiency of a system but also its longevity.” This statement underscores the importance of understanding the different types of high heat wires available and their respective applications in extreme conditions.

From aerospace to industrial heating systems, the need for wires that can withstand elevated temperatures has become increasingly vital. High heat wires are designed to endure severe thermal environments while maintaining conductivity and structural integrity. This article delves into the top 10 best high heat wire types for extreme temperature applications, exploring their unique properties and ideal use cases. Understanding these options will help engineers and technicians make informed decisions that enhance performance and reliability in demanding settings. As we navigate through these high heat wire types, we will highlight the distinct attributes that make each suitable for specific applications, ensuring that your projects can thrive in the harshest of conditions.

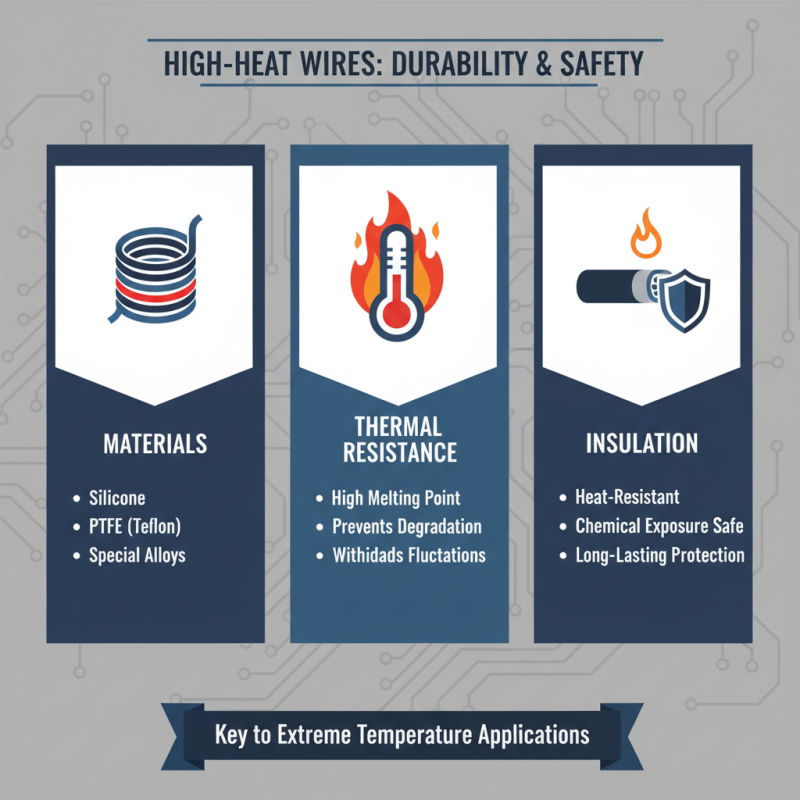

In extreme temperature environments, selecting the right high heat wire type is crucial for ensuring safety and performance. High heat wires are specifically designed to withstand elevated temperatures without degrading, making them ideal for applications such as aerospace, industrial machinery, and high-performance automotive systems. Common materials used for these wires include silicone, PTFE (Teflon), and fiberglass, each offering distinct advantages depending on the operational context.

Silicone wires are favored for their flexibility and ability to resist high temperatures, often exceeding 200°C. They are particularly useful in applications that require bending or movement without compromising integrity. On the other hand, PTFE wires present excellent chemical resistance alongside their high-temperature capabilities, making them suitable for harsh environments found in laboratories and chemical processing. Fiberglass wire insulation can tolerate extreme temperatures and provides robust mechanical protection, which is invaluable in industrial settings where abrasion and exposure to the elements are prevalent. Understanding the characteristics of these wires aids in choosing the most appropriate type for specific high heat applications, ensuring reliability and durability throughout their lifecycle.

When it comes to high heat wires, their key characteristics play a pivotal role in ensuring durability and safety in extreme temperature applications. These wires are typically made from materials that can withstand high thermal stress, such as silicone, PTFE, or specific alloys. Their high melting points and resistance to thermal degradation make them ideal for environments that experience rapid temperature fluctuations. Additionally, the insulation surrounding these wires is crucial; it should be both heat-resistant and capable of withstanding chemical exposure to prevent breakdown over time.

When selecting high heat wires, it’s essential to consider not only the temperature range but also the wire's flexibility and resistance to mechanical stress. Wires that maintain their performance under bending or stretching are particularly beneficial in dynamic applications.

**Tips:** Always check the wire’s rating to ensure it meets your specific application needs. Regular inspections can help identify any signs of wear or insulation breakdown before they lead to failures. Additionally, keep in mind that proper installation techniques are vital to maintaining wire longevity, especially in harsh conditions.

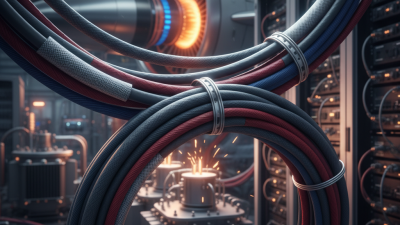

When it comes to extreme temperature applications, selecting the right high heat wire is crucial for performance and safety. High heat wires are designed to withstand elevated temperatures without degrading, making them ideal for industries such as aerospace, automotive, and manufacturing. Common materials used for these wires include silicone rubber, fluoropolymer, and fiberglass insulation, each providing unique advantages suited to specific environments.

For instance, silicone rubber is often used in environments where flexibility and high-temperature resistance are needed, such as in automotive engine compartments. Its ability to remain supple and resistant to various chemicals makes it a popular choice. On the other hand, fluoropolymer wires, known for their excellent electrical insulation properties, are ideal for applications involving extreme heat coupled with electrical demands, such as in certain aerospace components. Meanwhile, fiberglass-insulated wires find their place in high-temperature furnaces and industrial ovens due to their durability against thermal stress and exposure to aggressive conditions. Choosing the right high heat wire not only ensures operational efficiency but also enhances the longevity of the equipment used in challenging applications.

| Wire Type | Max Temperature (°C) | Insulation Material | Typical Applications |

|---|---|---|---|

| Silicone Rubber Wire | 200 | Silicone | Automotive, appliances |

| PTFE Wire | 260 | PTFE | Aerospace, laboratories |

| Kapton Wire | 260 | Kapton | Space applications, electronics |

| Fiberglass Insulated Wire | 350 | Fiberglass | Industrial equipment, heating elements |

| Mica Insulated Wire | 450 | Mica | Heating systems, motors |

| Ceramic Wire | 900 | Ceramic | High-temperature furnaces |

| Teflon Insulated Wire | 260 | Teflon | Medical devices, aircraft |

| Varnished Copper Wire | 180 | Varnish | Electric motors, transformers |

| Heat-Resistant Plastic Wire | 200 | Polyamide | Home appliances, machinery |

| High-Temperature Silicone Wire | 220 | Silicone | Food processing, robotics |

In extreme temperature applications, selecting the appropriate high heat wire type is crucial for ensuring both safety and performance. Conductivity plays a vital role in the efficiency of thermal management systems, and different wire materials exhibit varying levels of electrical conductivity. For instance, copper and aluminum are commonly used due to their excellent conductivity properties, while more specialized materials like nickel-chromium alloys provide better performance in high-temperature environments. Evaluating the conductivity of these materials allows for effective heat dissipation and minimizes energy loss, which is essential in demanding applications.

Temperature resistance is another critical factor in the selection of high heat wires. Materials such as silicone rubber and fiberglass-insulated wires can withstand extreme temperatures without degradation, making them ideal for situations where wires are exposed to harsh environments. The ability of a wire to maintain its integrity at elevated temperatures not only extends the lifespan of the wiring but also enhances safety by reducing the risk of failures that can lead to short circuits or other hazards. A thorough comparative analysis of these attributes helps determine the best options for various high-temperature applications, ultimately contributing to improved efficiency and reliability.

When working with high heat wires in extreme temperature applications, proper installation and maintenance are crucial to ensure optimal performance and longevity. Begin the installation by carefully assessing the environment where the wires will be used, as factors such as exposure to moisture, mechanical stress, and extreme temperatures can significantly affect the wire’s lifespan. Use appropriate insulation and protective materials to shield the wires from external elements. Ensure that connections are tight and secure to prevent any electrical arcing, which can lead to overheating and possible failure.

Regular maintenance is equally important for high heat wires. It is recommended to conduct routine inspections to check for signs of wear or damage, particularly in high-stress areas. Look for insulation degradation, discoloration, or any fraying of the wires. If any issues are detected, address them immediately to prevent further damage. Additionally, keeping the wiring area clean and free of debris can help avoid overheating and ensure proper airflow around the wires. Adopting a proactive maintenance approach will not only enhance performance but also extend the lifespan of high heat wires in extreme settings.

This bar chart illustrates the temperature tolerance of various high heat wire types used in extreme applications. These wires are essential for ensuring reliable performance in harsh environments. The temperatures listed represent the maximum continuous operating temperature for each wire type.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.