In the realm of electrical engineering, the selection of materials plays a crucial role in the performance and safety of electrical systems. High temp wire is specifically designed to withstand extreme temperatures, making it essential for applications in industries such as aerospace, automotive, and manufacturing. According to the Frost & Sullivan report on the global wire and cable market, the demand for high-performance wire, particularly high temp wire, is expected to grow significantly—projected to reach an annual growth rate of over 5% by 2025. This increase is driven by advancements in technology and the need for more resilient materials that can endure harsh environmental conditions without compromising functionality.

Choosing the right high temp wire is not merely a matter of selecting a product that can tolerate heat; it involves understanding the specific requirements of your project, including temperature ratings, insulation types, and wire gauges. A comprehensive analysis presented in the IEEE Standards for wire specifications highlights that using the appropriate high temp wire can lead to enhanced operational efficiency and increased safety in high-stakes environments. As the industry evolves and innovation accelerates, it becomes imperative for engineers and project managers to make informed decisions regarding the selection of high temp wire, ensuring optimal performance and longevity in their electrical projects.

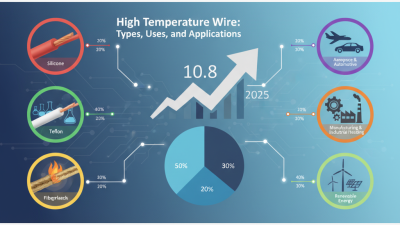

High temperature wires are essential components in electrical projects that require high heat resistance and durability. These wires are designed to operate efficiently in environments where temperatures exceed the limits of standard wiring. One of the key features of high temp wires is their insulation material, which is often made from synthetic compounds such as silicone, PTFE, or fiberglass. These materials not only withstand elevated temperatures but also provide resistance to various oils, chemicals, and environmental factors, making them ideal for applications in automotive, aerospace, and industrial settings.

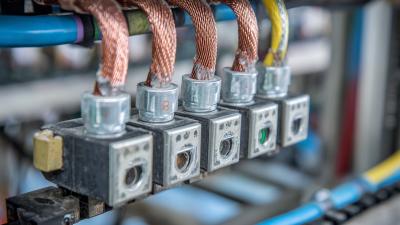

Another significant benefit of high temp wires is their enhanced performance in demanding conditions. They minimize the risk of electrical failures, short circuits, and degradation over time. High temp wires maintain their flexibility and structural integrity even at extreme temperatures, which is crucial for ensuring the safety and reliability of electrical connections. By employing high temperature wiring, engineers and technicians can extend the lifespan of their electrical systems while reducing maintenance costs and downtime, resulting in more efficient and sustainable operations.

When selecting high-temperature wire for your electrical projects, the first step is to clearly define the specific requirements of your project. Consider the environment where the wire will be installed, including temperature ranges and potential exposure to chemicals or moisture. High-temp wire is often necessary in applications such as industrial machinery, automotive components, or aerospace settings, where standard wire materials may fail under extreme conditions. Understanding these parameters will help narrow down your options and ensure that the wire can withstand the demands of your project without degrading over time.

Another crucial aspect to evaluate is the electrical specifications required by your project. Determine the wire gauge needed based on the current load and length of the wire run. Additionally, consider insulation types and their respective temperature ratings, as different materials offer varying degrees of heat resistance. It’s essential to select a wire that not only meets the thermal requirements but also aligns with the electrical safety standards to prevent potential hazards. Taking these factors into account will enable you to choose the most suitable high-temperature wire for a successful and reliable electrical installation.

When selecting the appropriate high-temperature wire for electrical projects, understanding the various types available and their specific applications is crucial. High-temperature wires are engineered to withstand extreme thermal environments, making them a staple in industries such as aerospace, automotive, and manufacturing. According to a market research report by Research and Markets, the global demand for high-temperature wires is expected to grow at a CAGR of 5.6% from 2022 to 2029, signaling the importance of selecting the right wire for durability and performance.

Among the commonly used high-temp wires, silicone-insulated wires are prominent due to their flexibility and resistance to harsh conditions. They can typically operate effectively at temperatures up to 200°C. These wires are ideal for applications in electric motors and generators, where both flexibility and heat resistance are vital. Another widely used type is Teflon (PTFE) insulated wire, which can endure temperatures from -60°C to 260°C. This makes it perfect for use in aerospace and high-performance automotive applications, where exposure to extreme conditions is routine. The choice between these types often hinges on the specific requirements of the application, including temperature ratings, wire gauge, and environmental exposure, ensuring the longevity and reliability of electrical systems.

When selecting the right high-temperature wire for your electrical projects, understanding the material quality and temperature ratings is paramount. The insulation materials commonly used for high-temp wires include silicone, PTFE (Teflon), and glass fiber, each displaying distinct thermoplastic properties. A recent analysis by the National Electrical Manufacturers Association (NEMA) indicates that silicone-insulated wires can withstand temperatures up to 200°C (392°F), making them ideal for applications in environments with extreme heat, such as automotive and aerospace industries. PTFE wires, on the other hand, can tolerate even higher temperatures, typically up to 260°C (500°F). The choice of insulation not only affects the wire's thermal compatibility but also its resistance to chemicals and mechanical stress.

Temperature ratings play a critical role in ensuring the longevity and safety of electrical installations. A comprehensive study published in the IEEE Electrical Insulation Magazine highlights that wires operating above their rated temperature can experience accelerated aging, leading to insulation failure and potential short circuits. In professional practice, it is essential to honor the manufacturer's specifications regarding temperature limits and any derating factors applicable to specific environments. For projects involving continuous exposure to high temperatures, it's advisable to select wires with ratings significantly higher than the maximum expected temperature, ensuring robust performance and reduced risk of failure over time.

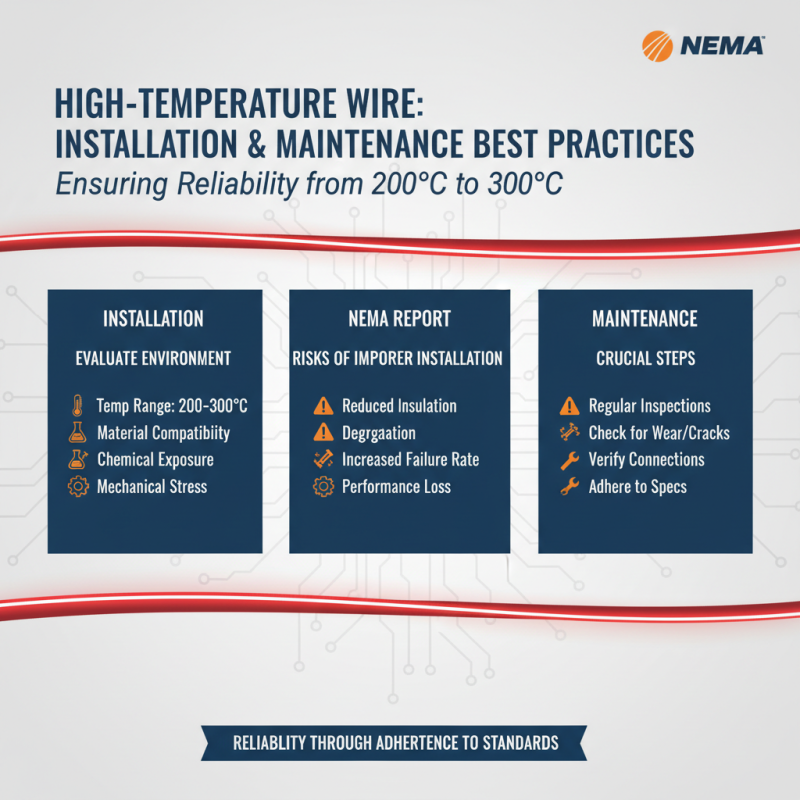

When it comes to the installation and maintenance of high temperature wires, adherence to best practices is crucial. High temperature wires are typically rated for temperatures ranging from 200°C to 300°C, depending on the materials used. According to a report by the National Electrical Manufacturers Association (NEMA), improper installation can lead to significant performance degradation, including reduced insulation integrity and increased risk of failure. Therefore, it’s essential to evaluate the environment in which the wire will be used, ensuring that the wire's insulation material is compatible with the surrounding conditions, whether they are mechanical or chemical in nature.

Proper installation techniques can enhance the longevity and reliability of high temperature wires. For instance, avoiding sharp bends and using suitable fittings can significantly reduce stress on the insulation. The American Wire Gauge (AWG) standards suggest that correct sizing is also key; using a wire gauge that is too small can generate excess heat due to resistance, potentially compromising the wire’s performance. Regular visual inspections and temperature monitoring, as suggested by the Institute of Electrical and Electronics Engineers (IEEE), can help in early detection of insulation wear or degradation. Establishing a routine maintenance program ensures that any potential issues are addressed proactively, ultimately extending the life of high temperature wiring in your electrical projects.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.