Choosing the right marine cable can be a daunting task. Experts in the marine cable industry suggest careful consideration of various factors. John Smith, a renowned marine cable specialist, once stated, "Selecting the correct marine cable is crucial for operational safety and efficiency."

When evaluating marine cables, one must consider the environment and specific usage. Will the cable be submerged in saltwater? Will it endure high temperatures? Each scenario calls for different specifications. For example, a cable used in deep-sea operations must be robust enough to withstand extreme pressures.

Also, reflect on the cable's insulation material. It plays a critical role in performance. Mistakes in this area can lead to significant issues. Often, people overlook the importance of compatibility with equipment. As John Smith points out, a small oversight can lead to larger operational failures. This knowledge is vital for making informed decisions.

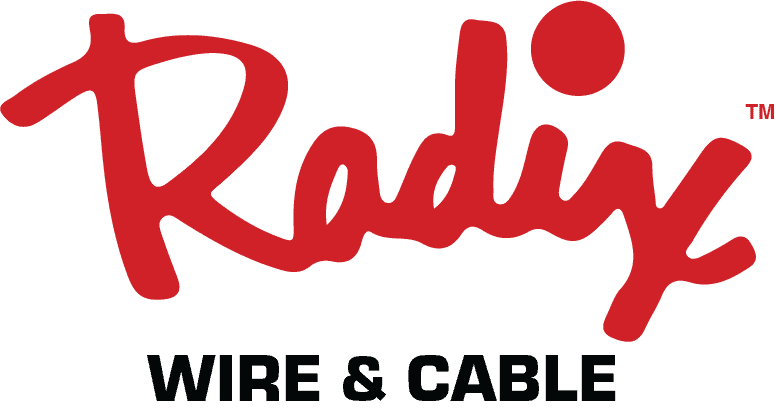

When selecting marine cables, understanding their types is crucial. Different cables serve specific functions and environments. For instance, power cables are essential for electrical systems aboard boats. They must withstand harsh marine conditions.

Communication cables, on the other hand, are designed for data transfer. These cables support navigation systems and other electronic devices. Choosing the right type ensures reliable performance. Many overlook the significance of environmental ratings, which indicate a cable's durability.

Consider the material as well. Copper and aluminum are common, each with pros and cons. Copper offers lower resistance but is heavier. Aluminum is lighter but may not conduct as effectively. Reflect on your unique needs. Proper selection avoids issues down the line, yet many rush this process. Take your time.

When selecting marine cables, several key factors matter. Start with the environment where the cables will be used. Saltwater can be harsh. Cables must resist corrosion to last long. Look for materials with high resistance to marine conditions. Insulation is crucial. The right insulation protects against water and chemicals.

Next, consider the cable's electrical capacity. Different applications require different current ratings. Misjudging this can lead to serious issues. Think about voltage drop too. Long distances can affect performance. Choose cables that minimize efficiency loss over distance.

Don’t overlook flexibility and handling. Cables should be easy to work with. Rigid cables may be hard to install in tight spaces. Evaluate the temperature range as well. Some cables can’t handle extreme cold or heat. Make sure you choose cables that can adapt and perform well under various conditions.

When selecting the right marine cable, consider the environmental conditions it will face. Saltwater, humidity, and temperature extremes can affect cable performance and lifespan. For instance, cables in coastal areas need to resist corrosion from salt and moisture. The right insulation material can make a big difference.

Tips: Always choose cables rated for marine use. Check the material to ensure long-lasting durability. If cables will be exposed to sunlight, select UV-resistant options.

It’s also important to think about installation environments. Some cables need to endure high-pressure areas, while others may be installed in warmer climates. Understanding the specific conditions will guide your choices. Regular inspections are necessary too. Cables can degrade over time, and proactive checks can prevent failures.

Tips: Look for cables with a higher temperature rating for hotter regions. Evaluate the potential exposure to chemicals, which can also deteriorate materials. Don't overlook the manufacturer's guidelines; they hold valuable insights.

Choosing the right marine cable is crucial for effective performance. Evaluating cable specifications can be daunting. Look for important details like conductor material, insulation type, and voltage rating. Copper and aluminum are common conductors. Copper shows better conductivity but may be more expensive.

Performance standards matter too. Review the temperature ratings and environmental resistance. Cables face harsh conditions at sea, from saltwater corrosion to extreme temperatures. Do not overlook these factors. Insulation materials such as PVC or XLPE can affect both durability and flexibility.

An often overlooked aspect is the length of the cable run. Longer cables can lead to voltage drop. This can affect equipment performance. Also, check for certifications. They ensure compliance with marine standards. Even the color coding should meet proper regulations for easy identification. It's essential to balance these factors based on your specific project needs.

| Cable Type | Voltage Rating | Conductor Material | Insulation Type | Water Resistance | Temperature Rating |

|---|---|---|---|---|---|

| Marine Power Cable | 600 V | Copper | PVC | Yes | -40°C to 90°C |

| Marine Communication Cable | 300 V | Aluminum | XLPE | Yes | -20°C to 75°C |

| Marine Data Cable | 300 V | Copper | PVC | Yes | -30°C to 70°C |

| Marine Control Cable | 600 V | Copper | PE | Yes | -40°C to 80°C |

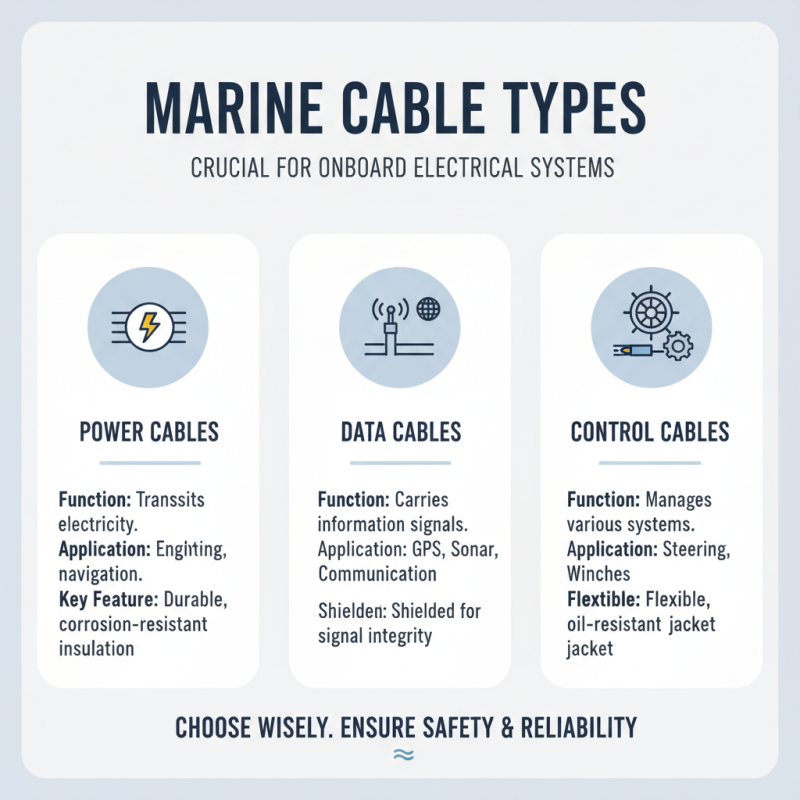

Marine cables are crucial for various applications in the marine environment. Proper installation and maintenance can significantly prolong their lifespan. According to industry reports, improper handling of marine cables can lead to performance issues and safety hazards. It is vital to follow best practices when working with these cables.

When installing marine cables, attention to detail is key. Ensure that the cables are not kinked or twisted during installation. A common mistake is neglecting environmental factors. Saltwater exposure can corrode cables over time. Protect connections with suitable marine-grade sealants. Monitoring cable tension can prevent certain types of damage.

Tip: Regularly inspect your cables for signs of wear or damage. Early detection can save costs and enhance safety.

During maintenance, cleaning regularly can keep cables in good condition. Using fresh water to rinse off salt and debris is effective. Remember, visual checks are important but not always enough. Sometimes, internal damage is not visible. Therefore, periodic cable testing can help identify hidden issues.

Tip: Document all inspections and maintenance activities. This record can be invaluable for future reference and decision-making.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.