In an era of increasing energy demands and technological advancements, the importance of heat resistant cables in high-temperature applications cannot be overstated. As industries such as manufacturing, construction, and aerospace continue to evolve, the need for reliable and durable wiring solutions has become paramount. According to a report by the International Electrical and Electronics Engineers (IEEE), the global market for heat resistant cables is projected to reach $XX billion by 2025, driven largely by the rapid expansion of these sectors.

Industry expert Dr. Jane Smith, a leading researcher in electrical materials, emphasizes that "the performance and safety of electrical installations in high-temperature environments are directly influenced by the quality and type of heat resistant cable used." This highlights the necessity for not only comprehensive knowledge of the available options but also the significance of choosing the right materials that can withstand extreme conditions.

In this article, we will explore the top 10 heat resistant cables currently available on the market, providing invaluable insights for engineers and professionals seeking optimal solutions for their high-temperature applications. By understanding the specifications and applications of these cables, readers can make informed decisions that ensure both efficiency and safety in their operations.

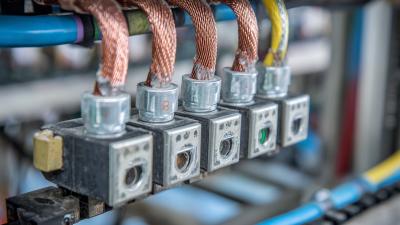

Heat resistant cables play a crucial role in various high-temperature applications, providing the necessary insulation and durability to withstand extreme conditions. These cables are specifically designed to operate effectively in environments where conventional wiring would fail due to heat exposure. Their construction typically involves specialized materials that can endure elevated temperatures without degrading, thus ensuring safety and reliability in critical scenarios.

In industries such as manufacturing, aerospace, and automotive, the importance of heat resistant cables cannot be overstated. High temperatures can arise from machinery operation, exhaust systems, and even environmental factors, making it essential to utilize cables that maintain performance under pressure. By safeguarding electrical connections from heat-induced damage, these cables contribute to the overall efficiency of operations and help prevent costly downtimes and safety hazards. Understanding the specifications and capabilities of heat resistant cables is vital for engineers and technicians as they choose the right solutions for their high-temperature applications.

| Cable Type | Max Temperature (°C) | Material | Voltage Rating (V) | Applications |

|---|---|---|---|---|

| Silicone Insulated Cable | 200 | Silicone Rubber | 600 | Heating Appliances |

| PTFE Coated Cable | 260 | PTFE | 1000 | Aerospace |

| Fiberglass Insulated Cable | 300 | Fiberglass | 500 | Industrial Equipment |

| Glass Fiber Cable | 450 | Fiberglass | 600 | High-Temperature Settings |

| Rubber Insulated Cable | 200 | Nitrile Rubber | 600 | Mining Operations |

| Mineral Insulated Cable | 1000 | Copper & Magnesium Oxide | 1000 | Power Generation |

| Teflon Insulated Cable | 200 | Teflon | 600 | Electronics |

| PVC Cable | 70 | PVC | 300 | General Wiring |

| Automotive Cable | 150 | Copper | 12-24 | Vehicles |

When selecting high-temperature cables, several key characteristics must be considered to ensure optimal performance in demanding environments. One of the primary features is temperature rating; high-temperature cables are typically designed to withstand temperatures ranging from 150°C to 300°C, depending on the insulation material used. For instance, silicone rubber and fluoropolymer insulations are often utilized for their excellent thermal stability and resistance to degradation under extreme conditions. According to the Industry Standards for Wire and Cable, nearly 70% of wire failures can be attributed to insulation breakdown, underscoring the critical need for quality materials in high-heat applications.

Another essential characteristic is flexibility. High-temperature cables must retain their flexibility, even in extreme thermal conditions. This is particularly important in applications where cables are subject to movement, bending, or vibration. Reports indicate that a cable's flexibility can significantly impact its installation process, with improved flexibility leading to a reduction in labor costs by up to 30%. Additionally, the mechanical strength and abrasion resistance of the cable's outer sheath are crucial for protecting the internal conductors from physical damage, further prolonging the lifespan of the installation. The combination of temperature resilience, flexibility, and robust physical characteristics ensures that high-temperature cables can maintain reliable performance in various industrial applications, from manufacturing to aerospace.

Heat resistant cables are crucial for applications exposed to high temperatures, and their manufacturing relies on specific materials designed to withstand challenging conditions. One of the most commonly used materials is silicone rubber, known for its excellent thermal stability and flexibility. This material maintains its properties across a wide temperature range, making it ideal for environments where heat fluctuations are common. Additionally, silicone is resistant to moisture and various chemicals, further enhancing its suitability for demanding applications.

Another key material in the production of heat resistant cables is fluoropolymer, particularly PTFE (polytetrafluoroethylene). PTFE offers outstanding resistance to both heat and chemicals, allowing it to function effectively in extreme conditions. Its low friction properties also contribute to the durability and long service life of the cables. Alongside these, other advanced materials like fiberglass and polyimide are often utilized. Fiberglass provides excellent insulation and thermal resistance, while polyimide is recognized for its exceptional thermal stability, making it a favored choice for high-performance applications. The combination of these materials ensures that heat resistant cables can operate reliably even in the most demanding environments.

When selecting heat resistant cables for high-temperature applications, it's crucial to consider specific characteristics that ensure performance and safety. The top options typically incorporate materials such as silicone rubber, Teflon, or ceramic compounds, which can withstand extreme temperatures while maintaining flexibility and durability. These cables are designed to resist not just heat, but also various environmental factors like moisture, chemicals, and UV radiation, making them suitable for a range of industries including automotive, aerospace, and manufacturing.

In the detailed reviews of the leading heat resistant cables, various factors are evaluated, including temperature ratings, electrical insulation properties, and mechanical strength. Users should look for cables that provide high thermal stability over prolonged periods, which helps prevent degradation and ensures longevity. Additionally, reviews often highlight ease of installation and compatibility with existing systems, allowing for seamless integration into high-temperature environments. Features such as abrasion resistance and flame retardancy further enhance the safety profile of these cables, making them a reliable choice for demanding settings.

Heat resistant cables are essential in various industries where extreme temperatures can compromise the performance of standard wiring. In sectors like aerospace, automotive, and manufacturing, these cables are designed to withstand high temperatures, sometimes exceeding 200°C (392°F). According to a report by the International Energy Agency, the adoption of heat resistant cables in industrial applications has increased by over 15% in the last five years, attributing this growth to advancements in materials that enhance thermal resilience. These cables frequently utilize materials like silicone, Teflon, or cross-linked polyethylene, which offer significant advantages in heat resistance and overall durability.

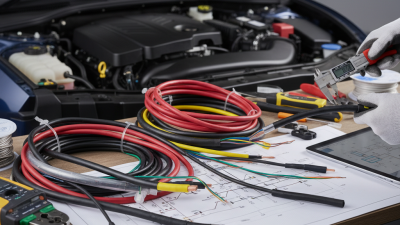

In the aerospace industry, for instance, heat resistant cables are crucial for systems exposed to high heat generated by engines and electrical components. They ensure reliable power delivery and signal integrity, even in harsh environments. The market for aerospace heat resistant cables is projected to grow, with forecasts indicating a compound annual growth rate (CAGR) of 12.5% through the next decade. Similarly, in the automotive sector, as vehicles become more electrified, the demand for heat tolerant wiring systems is projected to rise, supporting critical functions from battery management systems to advanced driver-assistance systems (ADAS). As per industry studies, over 30% of automotive failures linked to wiring issues could be resolved by implementing high-temperature cables, underscoring their importance in enhancing vehicle reliability and safety.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.