High temp cable is a critical component in a variety of industrial applications, specifically engineered to withstand extreme temperatures and harsh environmental conditions. With the rapid advancement of technology and the increasing demands in sectors such as aerospace, automotive, and energy, the need for reliable and durable wiring solutions has never been more significant. As industry expert Dr. Emily Thompson states, "The performance and safety of high temp cable in extreme conditions cannot be overstated; it is essential for efficient operation in many of today’s high-stakes environments."

These specialized cables offer remarkable resistance to heat, chemicals, and abrasion, making them indispensable in processes ranging from manufacturing to electrical generation. The versatility of high temp cable allows it to be utilized in diverse scenarios, including engine compartments of vehicles, power generation facilities, and even the telecommunications industry, where exposure to excessive heat can be detrimental. As industries continue to evolve and face new challenges, the role of high temp cable becomes increasingly vital in ensuring reliable performance and safety in operations.

High temperature cables are designed to operate in environments where conventional cables cannot withstand the heat. These cables are constructed using specialized materials that allow them to endure extreme temperatures, typically exceeding 150 degrees Celsius (302 degrees Fahrenheit). The outer insulation is often made from high-performance polymers like silicone rubber or fluoropolymers, providing not only thermal resistance but also protection against chemicals, oils, and abrasion, which are common in high-temp applications.

One of the defining characteristics of high temperature cables is their flexibility, which allows for easy installation in complex environments. This flexibility does not sacrifice durability; these cables can endure repeated flexing and movement without losing their integrity. Besides heat resistance, high temp cables also possess excellent electrical properties, making them suitable for a wide range of applications including aerospace, automotive, industrial machinery, and power generation. In these industries, reliability and safety are paramount, and using high temperature cables ensures that electrical systems remain functional even under challenging conditions, ultimately minimizing downtime and maintenance costs.

High temperature cables are engineered to withstand extreme thermal conditions, making them essential in various industrial applications. The construction of these cables involves specific materials designed to provide durability and reliability in high-heat environments. Typically, high temp cables utilize insulating materials such as fluoropolymers, silicone rubber, and fiberglass, all chosen for their ability to resist degradation at elevated temperatures.

Fluoropolymer insulation, for instance, is recognized for its remarkable thermal stability and chemical resistance, often functioning efficiently in environments exceeding 200°C. Silicone rubber is another popular choice due to its flexibility and high heat tolerance, making it ideal for applications where movement is crucial. Additionally, fiberglass reinforced designs offer excellent mechanical protection and are used in applications where both heat resistance and physical strength are required. By combining these advanced materials, high temp cables provide reliable performance in industries like aerospace, automotive, and manufacturing, ensuring safety and efficiency under challenging conditions.

| Application Industry | Temperature Rating (°C) | Common Materials Used | Key Features |

|---|---|---|---|

| Aerospace | 200 | PTFE, Fiberglass | Lightweight, Flexibility |

| Automotive | 125 | Silicone, PVC | Chemical Resistance |

| Industrial Manufacturing | 150 | Hight Temp Nylon, Silicone | Durability, Energy Efficiency |

| Power Generation | 300 | XLPE, Fluoropolymers | High Voltage, Thermal Resistance |

| Oil and Gas | 250 | Metallic Shields, Teflon Coatings | Corrosion Resistance |

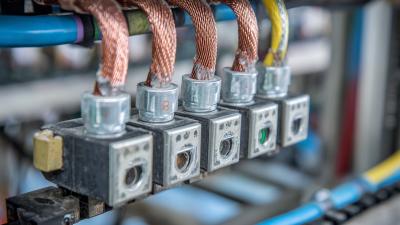

High temperature cables are designed to

withstand extreme heat environments, making them essential in various industries. One of the key applications of high temp

cables is in the aerospace sector, where these cables are used in aircraft engines and wiring systems that encounter severe

thermal stress. Their ability to maintain conductivity and insulation properties at elevated temperatures ensures the

safety and reliability of these critical systems during flight operations, where failure is not an option.

Another significant application is found in the manufacturing and processing industries, particularly in high-temperature

furnaces and ovens. High temp cables are utilized to connect sensors, controllers, and other equipment that operate in

extreme conditions, ensuring that production processes run smoothly and efficiently. The chemical industry

also benefits from these cables, as they can withstand aggressive environments without deteriorating, thus ensuring the

integrity of electrical systems operating in plants that produce chemicals and petrochemicals. Overall, high temperature

cables are vital components that enhance safety and performance in these demanding applications.

High temperature cables are specifically designed to withstand extreme thermal conditions, making them ideal for harsh environments found in various industries such as aerospace, automotive, and manufacturing. One of the primary advantages of using high temp cables is their ability to maintain performance despite exposure to intense heat. These cables are typically made with specialized insulation materials that resist degradation, ensuring longevity and reliability even in the most challenging conditions. This durability minimizes the risk of failures that could lead to downtime or safety hazards, making them invaluable in critical applications.

Another significant benefit of high temperature cables is their enhanced flexibility and resilience under mechanical stress. In industries where equipment is frequently moved or subject to vibrations, traditional cables may fracture or degrade more quickly. High temp cables, however, are engineered to endure such environments without compromising their structural integrity. This quality not only improves the overall efficiency of operations but also reduces maintenance costs and the need for frequent replacements, contributing to more sustainable industrial practices. By incorporating high temperature cables, businesses can achieve greater reliability and performance in their systems, ultimately leading to improved productivity and safety.

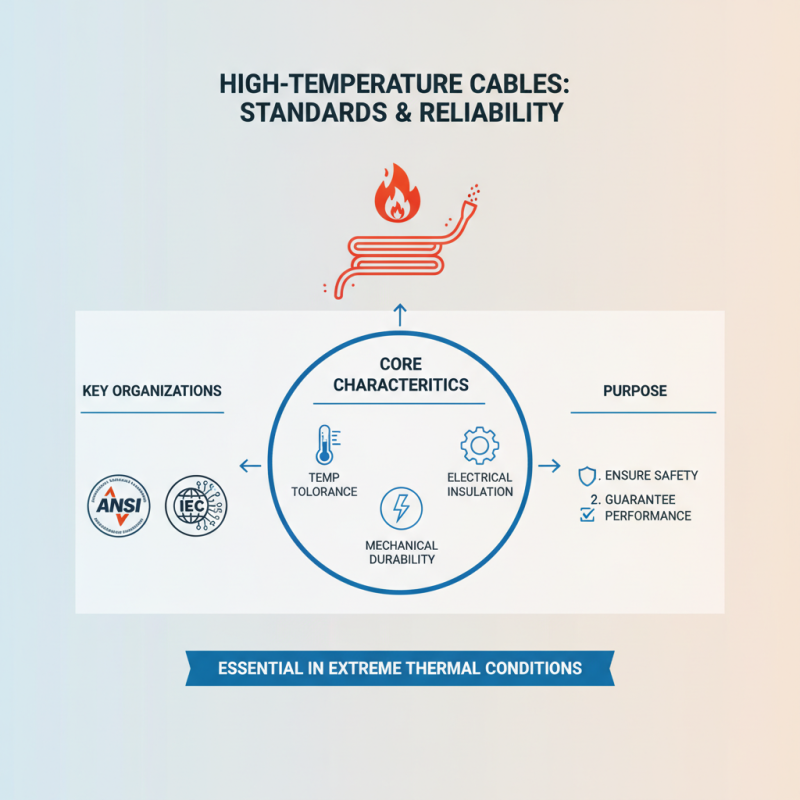

High temperature cables are essential components in various industries that operate under extreme thermal conditions. To ensure their reliability and safety, these cables must adhere to specific standards and certifications. These standards are designed to evaluate their performance in high-heat environments, dictating parameters such as temperature tolerance, electrical insulation integrity, and mechanical durability. Organizations such as the American National Standards Institute (ANSI) and the International Electrotechnical Commission (IEC) establish these criteria, providing a framework for manufacturers to develop high-temp cables that meet rigorous safety and performance expectations.

In addition to ANSI and IEC standards, various industries may require compliance with specialized certifications, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) approvals. These certifications guarantee that the cables have undergone testing for specific applications, including aerospace, automotive, and industrial settings. By adhering to these standards and obtaining the necessary certifications, manufacturers can assure end-users of the cables' reliability, thereby helping to prevent failures in critical systems that could lead to costly downtime or safety hazards. This rigorous oversight ensures that high temperature cables not only perform optimally but also align with industry best practices for safety and efficiency.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.