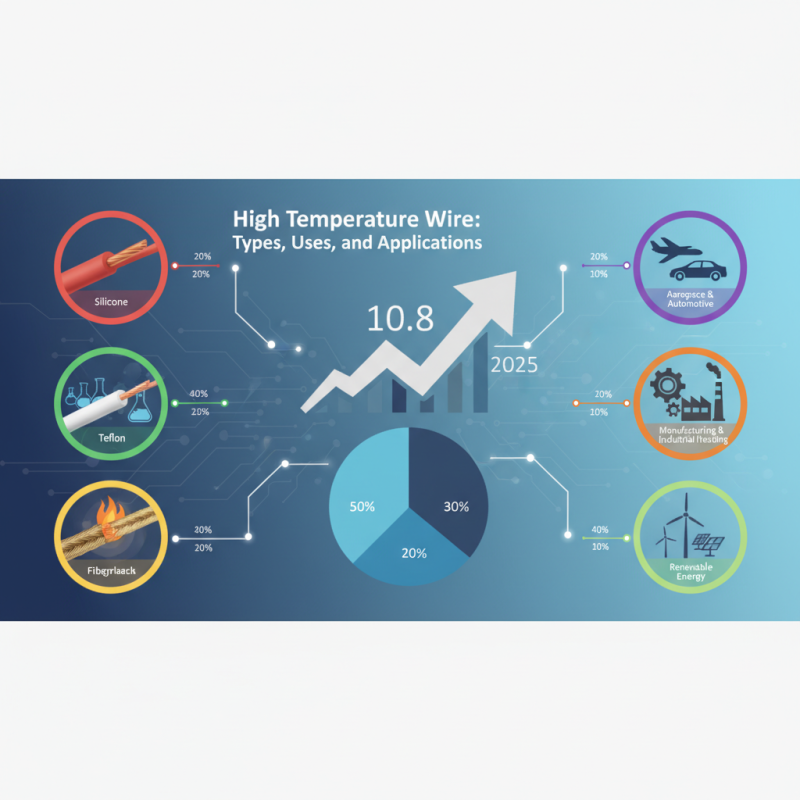

High temperature wire is a critical component in various industries, playing a vital role in the functionality and reliability of numerous electrical systems. Defined by its ability to withstand extreme temperatures, this specialized wiring is essential in sectors ranging from aerospace to automotive and manufacturing. According to a recent industry report by Grand View Research, the global market for high temperature wire is projected to reach USD 10.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is driven by the increasing demand for durable and reliable electrical solutions in high-performance applications.

The types of high temperature wire available are diverse, each designed to meet specific operational needs dictated by their environment. Silicone, Teflon, and fiberglass insulated wires are among the most common, each providing unique benefits such as chemical resistance, flexibility, and insulation durability. As technologies evolve, industries are seeking materials that not only perform under stringent thermal conditions but also enhance safety and longevity. Understanding the various uses and applications of high temperature wire becomes paramount for engineers and procurement specialists aiming to select the right solution for their projects. Whether in high-voltage applications, industrial heating, or even renewable energy systems, high temperature wire is integral to ensuring robust performance and reliability under extreme conditions.

High temperature wires are essential components in numerous industrial applications, designed to withstand extreme thermal environments without compromising performance. Among the various types of high temperature wire, silicone insulated wire is particularly notable for its flexibility and resistance to heat, making it ideal for automotive and aerospace applications. According to a report by the International Wire and Cable Association, silicone insulated wires can operate efficiently at temperatures up to 200°C (392°F), while maintaining excellent dielectric properties even under stress.

Another common type is mica tape wire, which features a unique combination of high dielectric strength and thermal resistance, capable of withstanding temperatures exceeding 300°C (572°F). This wire is particularly beneficial in sectors such as electrical insulation in windings and transformers, where high durability is essential. In fact, a study by the National Electrical Manufacturers Association highlights that mica tape wire reduces the risk of failure in high-temperature environments, greatly enhancing system reliability.

Tips: When selecting high temperature wire, always consider the specific temperature limits and environmental factors of your application. It's also advisable to consult technical datasheets to understand the characteristics and compatibility of different wire types. Remember, proper installation and maintenance can significantly extend the lifespan of high temperature wires in demanding settings.

| Type of Wire | Maximum Temperature | Material | Typical Uses | Characteristics |

|---|---|---|---|---|

| Silicone Wire | 200°C | Silicone rubber insulated copper | Automotive, aerospace, high-performance applications | Flexible, resistant to moisture and chemicals |

| Teflon Wire | 260°C | PTFE insulated copper | Electronics, military, industrial applications | High chemical resistance, low friction |

| Mineral Insulated Wire | 1200°C | Copper with magnesium oxide insulation | Industrial furnaces, petrochemical operations | Robust, withstands extreme temperatures and environments |

| Kapton Wire | 200°C | Polyimide insulated copper | Aerospace, electronics, and high-temperature environments | Thin, lightweight, excellent dielectric properties |

| Glass Braided Wire | 500°C | Copper or aluminum wire with glass insulation | High-temperature electric motor leads, appliance wires | Good thermal resistance, durable insulation |

High temperature wires are essential components in various industries where electrical conductivity must withstand extreme conditions. Commonly used materials in the manufacturing of high temperature wire include silicone rubber, PTFE (Polytetrafluoroethylene), and various metal alloys such as nickel and tungsten. These materials are carefully selected based on their thermal resistance, chemical stability, and mechanical properties, enabling their use in applications ranging from aerospace to industrial machinery.

Silicone rubber is often favored for its impressive temperature tolerance, typically ranging from -55°C to 200°C, with some formulations able to withstand even higher temperatures. According to a report by the International Wire and Cable Manufacturers, silicone rubber wires maintain flexibility at extreme temperatures, making them suitable for environments where high thermal cycling occurs.

PTFE wires are known for their non-stick properties and exceptional electrical insulation, allowing them to perform reliably in applications exposed to harsh chemicals or high temperatures, up to 260°C.

Nickel and tungsten alloys are prevalent in applications requiring high mechanical integrity and conductivity. Reports indicate that these alloys exhibit excellent resistance to oxidation and wear, which is critical in harsh operating environments. Moreover, nickel-based wires can endure temperatures exceeding 1000°C, making them ideal for furnace and industrial applications where traditional materials would fail. The choice of material greatly influences the wire’s performance, ensuring safety and reliability in demanding conditions.

High temperature wire is an essential component across various industries due to its ability to withstand extreme heat and harsh environmental conditions. In the aerospace sector, high temperature wire is crucial for the safe operation of aircraft systems. According to a report from MarketsandMarkets, the aerospace industry is projected to grow at a compound annual growth rate (CAGR) of 4.6% from 2021 to 2026, driving the demand for reliable wiring solutions that can endure high thermal stress. These wires are often used in engine components and electric systems, ensuring safety and performance under intensive operational conditions.

In the automotive sector, high temperature wires are utilized in advanced systems such as engines, exhausts, and turbochargers, where temperatures can spike significantly. An industry analysis shows that the global automotive wiring harness market is expected to reach USD 69.13 billion by 2026, with high temperature wire being a significant segment of this growth. Manufacturers are increasingly focusing on developing materials that enhance heat resistance and durability, allowing for longer lifespans and improved efficiency in automotive applications.

Tips for selecting the right high temperature wire include considering the maximum temperature your application will encounter, the type of insulation needed, and the wire gauge appropriate for your specific current requirements. It's also advisable to consult with industry professionals to ensure compliance with safety standards and regulations relevant to your field. Engaging with experts can lead to better material selection that balances performance with cost-effectiveness, ultimately enhancing project outcomes.

When dealing with high temperature wires, it is crucial to consider the safety standards and regulations that govern their production and use. These wires are typically rated to withstand extreme conditions, with some capable of operating at temperatures as high as 1000 degrees Fahrenheit. According to the National Electrical Code (NEC), high temperature wires must meet certain specifications to ensure they provide adequate insulation and protection against electrical failures in high-heat environments. This includes compliance with materials like silicone, Teflon, or mica, which enhance the wire's thermal resistance and durability.

Moreover, organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC) have established rigorous testing protocols to certify high temperature wires. These certifications ensure that the materials used not only resist thermal degradation but also maintain their electrical integrity over time. Recent industry reports indicate that the growth of sectors such as aerospace, automotive, and industrial machinery, which demand reliable high temperature wiring solutions, has led to an increased emphasis on compliance with these safety standards. For example, a report by MarketsandMarkets projected that the global market for high temperature wires will reach $3.1 billion by 2025, underscoring the critical role these standards play in fostering product reliability and user safety.

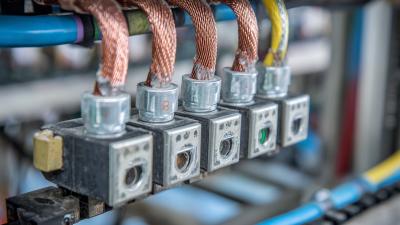

When handling high temperature wires, proper maintenance and handling practices are essential to ensure their longevity and performance. High temperature wires are designed to withstand extreme conditions, with insulation materials like PTFE and silicone rubber providing resistance to heat and various chemicals. According to industry reports, when exposed to temperatures exceeding 200°C, premature degradation can occur if wires are not appropriately maintained. Regular inspections for signs of wear, such as fraying or discoloration, can help identify issues early.

**Tips**: Use high-temperature gloves when handling wires, especially in industrial settings, to prevent injuries. Always follow manufacturer’s recommendations during installation, ensuring that connections are secure to minimize the risk of failure.

When storing high temperature wires, it is crucial to keep them in a cool, dry environment away from direct sunlight. Humidity can lead to corrosion of metal conductors, while excessive heat can compromise insulation integrity. When transporting these wires, avoid bending or twisting them sharply, as this can damage the protective layers and affect performance under high temperatures.

**Tips**: Consider using protective tubing or reels to safeguard wires during storage and transport. Implementing a rotation system for inventory can also ensure older stock is used first, preventing degradation over long periods.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.