In today's ever-evolving technological landscape, the demand for reliable and efficient materials is paramount, especially in extreme environments where traditional wiring solutions fall short. High temperature wire stands out as a critical component in various applications, providing the necessary durability and performance to withstand intense heat and challenging conditions. This comprehensive guide will explore the top ten high temperature wires that are engineered to excel under such rigorous circumstances.

Understanding the characteristics and advantages of high temperature wire is essential for engineers, manufacturers, and technicians who are tasked with designing and maintaining systems in industries ranging from aerospace to automotive and beyond. These wires are specifically formulated to resist thermal degradation, ensuring continued functionality and safety where other materials might fail. As we delve into this guide, we will highlight the unique features, advantages, and ideal applications for each type of wire, empowering you to make informed decisions when selecting high temperature wiring solutions for your projects.

High temperature wires are specialized electrical conductors designed to operate reliably in extreme conditions where traditional wires would fail. These wires are essential in various industries, including aerospace, automotive, and manufacturing, where they are exposed to elevated temperatures, corrosive environments, and mechanical stress. The construction of high temperature wires typically involves insulation materials such as silicone, fluoropolymer, or mica, which can withstand substantial heat while maintaining electrical integrity. Their ability to function effectively under such conditions makes them crucial for the safety and efficiency of critical systems.

Applications of high temperature wires are vast and varied. In the aerospace sector, they are used in engine controls, ignition systems, and various electronic components that operate in high-heat areas. The automotive industry similarly relies on these wires for applications in engines, exhaust systems, and under-hood electronics. Additionally, manufacturing processes that involve furnaces or other high-temperature equipment often necessitate the use of specialized wiring solutions to prevent failures that could lead to downtime or equipment damage. By utilizing high temperature wires, industries can enhance performance, ensure safety, and extend the operational lifespan of critical components in extreme environments.

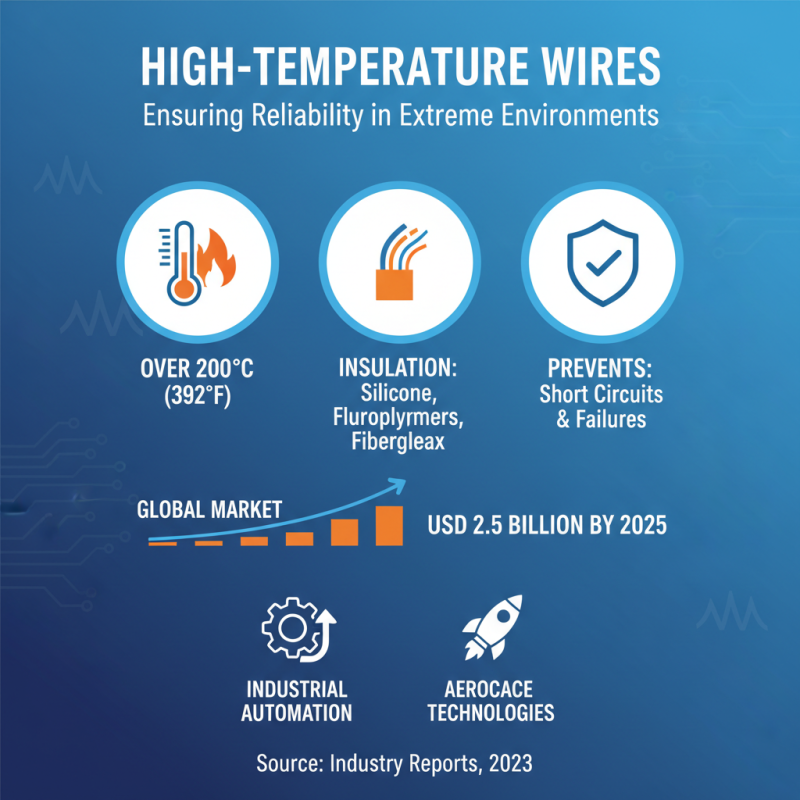

When dealing with extreme environments, the selection of high-temperature wires is crucial for ensuring reliability and safety. High-temperature wires are designed to withstand prolonged exposure to elevated temperatures, often exceeding 200°C (392°F). These wires typically feature insulation materials such as silicone rubber, fluoropolymers, or fiberglass that maintain their integrity under thermal stress, preventing short circuits and failures in critical applications. Reports indicate that the global market for high-temperature wires is projected to reach USD 2.5 billion by 2025, driven by advancements in industrial automation and aerospace technologies.

Key properties to consider when selecting high-temperature wires include thermal stability, chemical resistance, and flexibility. Thermal stability ensures that the wire can continue to function at high temperatures without degrading, while chemical resistance is vital for environments exposed to corrosive agents. Flexibility is particularly important for applications that require movement or bending, as it minimizes the risk of wire fatigue. According to a recent industry analysis, wires with superior thermal properties can maintain performance at temperatures as high as 300°C (572°F) without compromising electrical efficiency.

Tips: Always consult the manufacturer's data sheets for maximum temperature ratings and specific chemical compatibility to ensure the selected wire meets the demands of your application. Additionally, consider the environment where the wire will be installed to select the appropriate insulation material that can withstand both thermal and mechanical stresses.

When selecting high temperature wires for extreme environments, it's crucial to consider specifications that cater to the demanding conditions. One of the key features to look for is the temperature rating, which indicates the maximum thermal exposure the wire can withstand without degrading. High temperature wires are typically designed to operate safely at temperatures ranging from 200°C to over 1000°C, making them suitable for applications in industries like aerospace, automotive, and heavy manufacturing.

Additionally, the insulation material plays a vital role in the wire's performance. Common insulations include silicone rubber, PTFE, and fiberglass, each offering unique thermal resistance and mechanical properties.

Another important specification is the wire's resistance to chemical agents and mechanical stress. Many high temperature wires are engineered to be resistant to corrosion, abrasion, and harsh chemicals, ensuring longevity in environments where exposure is inevitable. Flexibility and ease of installation are also notable features, as certain applications may require wires that can withstand frequent bending or movement.

Moreover, understanding the wire gauge is essential, as it impacts electrical conductivity and heat dissipation, which are critical factors in maintaining optimal performance in high temperature settings. Selecting the right combination of these specifications ensures reliability and efficiency in even the most extreme conditions.

When selecting high temperature wires for extreme environments, several critical factors come into play to ensure safety and performance. Firstly, it's essential to assess the temperature rating of the wire material. For instance, wires made from materials such as PTFE (Polytetrafluoroethylene) can typically withstand temperatures up to 260°C, while ceramic-insulated wires may function effectively even at temperatures exceeding 1000°C. Understanding the operational heat range required for your application is crucial for avoiding premature failure and ensuring longevity.

Additionally, insulation type and durability are paramount. High temperature wires are often exposed to harsh conditions, so the insulation must resist not just high temperatures but also factors like abrasion, moisture, and chemicals. According to industry reports, high performance insulation materials, like those based on silicone or mica, offer superior resilience in extreme environments. The choice of conductor material also affects performance; for instance, nickel-coated copper is favored for its excellent conductivity and resistance to oxidation at elevated temperatures.

Finally, it is vital to consider the wire's mechanical properties, such as flexibility and tensile strength, especially in applications where wires might be subject to movement or stress. Research conducted by industry experts indicates that flexible high temperature wires can enhance installation efficiency and reduce the risk of wire fatigue. By carefully evaluating these factors, manufacturers and engineers can select the most suitable high temperature wires for their specific application needs, ensuring reliability and performance in extreme conditions.

| Wire Type | Max Operating Temperature (°C) | Material | Insulation Type | Applications |

|---|---|---|---|---|

| Silicone Wire | 200 | Copper | Silicone Rubber | Automotive, Aerospace |

| PTFE Wire | 260 | Copper | PTFE | High Frequency, Electrical |

| Glass Fiber Wire | 300 | Copper | Glass Fiber | Industrial, Marine |

| Kapton Wire | 400 | Copper | Kapton | Aerospace, Military |

| Fiberglass Insulated Wire | 350 | Copper | Fiberglass | Heavy Machinery, Heating |

| Ceramic Wire | 800 | Nickel | Ceramic | High-Temperature Furnaces |

| Teflon Wire | 260 | Copper | Teflon | Electronics, Communications |

| Inconel Wire | 1000 | Nickel-Chromium Alloy | Metal | Aerospace, Oil & Gas |

| Mica Wire | 400 | Copper | Mica | High Voltage, Heating Elements |

When dealing with high temperature wiring solutions, maintenance and care are crucial to ensure longevity and optimal performance, especially in extreme environments. High temperature wires, often rated to withstand temperatures exceeding 200°C (392°F), require specific handling and upkeep practices. Regular visual inspections can help identify wear and tear, oxidation, or insulation damage, which can compromise the effectiveness of the wiring. According to industry standards, a proactive maintenance schedule can reduce failure rates by as much as 30%, emphasizing the importance of routine check-ups.

Furthermore, proper installation techniques can significantly prolong the lifespan of high temperature wiring. It is essential to avoid sharp bends and unnecessary stress on the cables, as these can lead to premature failure. Utilizing appropriate connectors and securing wires to prevent movement can also mitigate risks. Regular cleaning, especially in environments with corrosive substances, is advised to maintain conductivity and insulation integrity.

**Tips for Maintaining High Temperature Wires:**

1. Conduct periodic thermal imaging to spot hotspots which might hint at potential failures.

2. Use proper protective gear during installation and maintenance to prevent damage to the wires.

3. Keep documentation of inspections and maintenance activities to track performance and identify trends over time. Maintaining a systematic approach will improve both safety and reliability in demanding conditions.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.