In the rapidly evolving world of electrical engineering and DIY projects, understanding how to effectively "hook up wire" has become essential for both professionals and enthusiasts alike. According to a report by the National Electrical Manufacturers Association (NEMA), the electrical equipment market in the United States is anticipated to surpass $200 billion by 2025, highlighting the growing demand for skilled knowledge in wiring techniques. As technology advances and energy-efficient solutions become paramount, the need for safe, reliable, and effective wiring practices cannot be overstated.

Properly hooking up wire not only enhances the performance of electrical systems but also significantly contributes to safety standards. The U.S. Energy Information Administration (EIA) notes that residential electricity consumption is rising, with an expected increase of 1.8% per year through 2025. This data underscores the importance of proficiency in electrical connections to meet both regulatory compliance and consumer needs. By employing best practices for hooking up wires, individuals can ensure optimal functionality and longevity of their electrical projects, ultimately preventing costly repairs or hazardous situations.

As we delve into the various techniques and tips for hooking up wire efficiently, it is crucial to embrace both traditional methods and modern innovations that cater to an ever-growing electrical landscape. Whether you are a seasoned electrician or embarking on a DIY venture, mastering the art of hooking up wire will undoubtedly empower you to tackle a wide range of electrical projects with confidence and expertise.

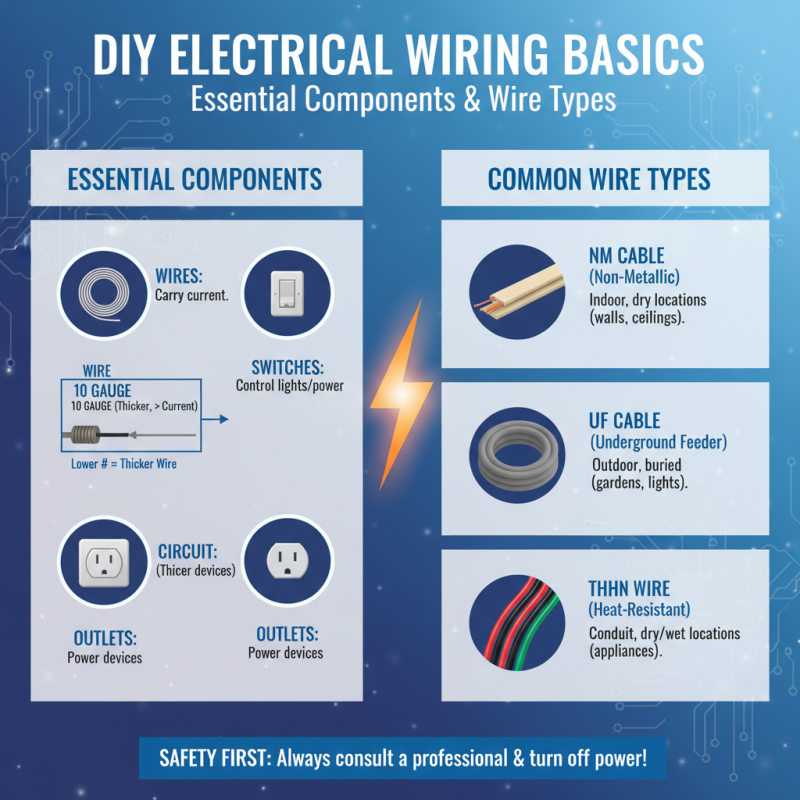

Understanding the basics of electrical wiring is crucial for anyone looking to engage in DIY electrical projects. Before starting, it’s important to familiarize yourself with essential components such as wires, switches, outlets, and circuit breakers. Each type of wire serves a specific purpose, typically categorized into types like NM (non-metallic sheathed cable), UF (underground feeder), and THHN (thermoplastic high heat-resistant nylon-coated wire). Knowing the proper gauge for your project can help ensure safety and efficiency, with lower gauge numbers indicating thicker wires designed for larger currents.

When hooking up wires, the fundamental principle is to always ensure safety first. This includes turning off the power at the circuit breaker before starting any work. As you begin your project, strip the insulation from the ends of the wires to expose the copper, and use wire connectors to secure connections. It’s crucial to match the wire colors: typically, black or red wires are used for hot connections, white wires for neutral, and green or bare wires for grounding. Following these basic guidelines allows for a smoother, safer hook-up process while enhancing your skills in working with electrical systems.

When embarking on electrical wiring projects, having the right tools and materials is crucial for ensuring safety and efficiency. Industry reports, such as the National Electrical Contractors Association (NECA) research, indicate that improper tools lead to a 30% increase in workplace accidents in electrical installations. Therefore, equipping yourself with essential tools can significantly minimize risks and improve productivity.

Key tools include wire strippers, pliers, screwdrivers, and a multimeter. Wire strippers allow for precise insulation removal without damaging the wire itself, which is essential for creating secure connections. Pliers and screwdrivers—often overlooked—are vital for securing fixtures and performing tasks that require a strong grip. Additionally, a multimeter is indispensable for troubleshooting electrical systems, allowing you to measure voltage, current, and resistance easily. According to the U.S. Bureau of Labor Statistics, proper tools not only enhance job performance but also reduce the time required to complete projects, with estimates showing a potential decrease in labor costs by up to 20%.

Moreover, selecting the right materials is just as important. High-quality wires, connectors, and circuit breakers are foundational elements for any successful project. Reports from the International Electrotechnical Commission indicate that using substandard materials can lead to failures in 15% of wiring installations. Investing in quality materials ensures greater durability and safety in your projects, ultimately resulting in long-term savings and peace of mind.

| Tool/Material | Description | Recommended Uses | Safety Tips |

|---|---|---|---|

| Wire Stripper | A tool used to remove insulation from electric wires. | Preparing wires for connections in electrical projects. | Always disconnect power before stripping wires. |

| Multimeter | An instrument for measuring voltage, current, and resistance. | Testing electrical outputs and ensuring circuits are safe. | Use with caution; ensure probes are used correctly to avoid shock. |

| Electrical Tape | Insulating tape used to secure and insulate electrical wires. | Securing connections and preventing shorts. | Make sure it’s wrapped tightly and fully covers exposed wires. |

| Connectors | Devices that join two or more electrical wires together. | Making secure connections in circuits. | Check compatibility with wire gauges to prevent overheating. |

| Wire Cutters | Used for cutting wires and cables. | Trimming wires to the desired length. | Always cut away from your body to prevent injury. |

| Voltage Tester | A simple device to check if a wire is carrying voltage. | Checking live wires before working. | Test the device on a known live circuit first. |

When embarking on electrical projects, understanding how to make solid wiring connections is crucial for safety and efficiency. This step-by-step guide will walk you through the essential processes involved in wiring connections. First, ensure that you have a clear workspace and wear appropriate safety gear, including gloves and goggles. Before starting any electrical task, always turn off the power supply to prevent accidents.

Next, gather all necessary tools and materials, such as wire strippers, pliers, electrical tape, and connectors. Begin by stripping the insulation from the ends of the wires, exposing enough copper to make a strong connection. For most residential projects, you will commonly encounter three types of wires: hot, neutral, and ground. Make sure to correctly identify these wires, as incorrect connections can lead to serious hazards.

Using the recommended connection methods, like twisting wires together or using wire nuts, will ensure a secure and lasting link. After connecting, wrap the junction with electrical tape to add an extra layer of insulation, facilitating safe operation for your electrical project.

When engaging in electrical projects, safety must always be the top priority. Before starting to hook up wires, ensure you are well-equipped with the appropriate tools and protective gear. Wearing insulated gloves and safety goggles will protect you from electrical shocks and any flying debris. Additionally, it is vital to turn off the power at the circuit breaker before handling any wires. This simple step can significantly reduce the risk of accidental electrocution.

Another critical safety precaution is to verify the wire connections before powering up your project. Using a multimeter can help ensure that everything is properly connected and grounded. Always double-check that the amperage ratings of the wires match the requirements of your electrical components. Furthermore, keeping your workspace tidy and free from clutter can prevent accidental trips and falls, which can lead to dangerous situations. By following these precautions, you can approach your electrical projects with confidence and peace of mind.

When dealing with electrical wiring issues, it's crucial to be aware of common problems that might arise, especially during the summer months when household appliance use surges.

Electrical overloads can lead to short circuits, which are a significant cause of domestic fires.

Data indicates that household fires in India increase substantially in summer due to outdated wiring and excessive demands on electrical systems.

Properly troubleshooting these issues can prevent catastrophic events.

One effective method for troubleshooting is to simplify your approach. For instance, if you're facing a problem with an electric motor, connect it directly to a battery to determine if it operates correctly.

This technique bypasses intricate setups and can quickly reveal if the problem lies in the wiring or the device itself.

It’s essential to inspect connections regularly and replace any frayed wires or faulty sockets to maintain safety and reliability.

Additionally, familiarizing yourself with common errors, such as those encountered with smart thermostats or well pumps, can empower homeowners to address issues before they escalate.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.