Installing underground wire is a critical task for any DIY enthusiast or professional electrician, as it provides a reliable way to power various outdoor features such as lighting, irrigation systems, and security measures. When done correctly, proper installation can enhance the safety and efficiency of your electrical systems while minimizing the risk of accidents or damage. However, the intricacies involved in effectively laying underground wire require careful planning, adherence to safety standards, and knowledge of local regulations.

Whether you are preparing for a new installation or upgrading an existing electrical system, understanding the nuances of underground wiring is essential. This guide aims to offer valuable tips and best practices that will help you navigate the process with confidence. From choosing the right type of wire and proper burial depth to avoiding common pitfalls, we will cover key considerations to ensure your underground wire installation is both safe and durable. By paying attention to the details, you can create a reliable underground electrical network that stands the test of time.

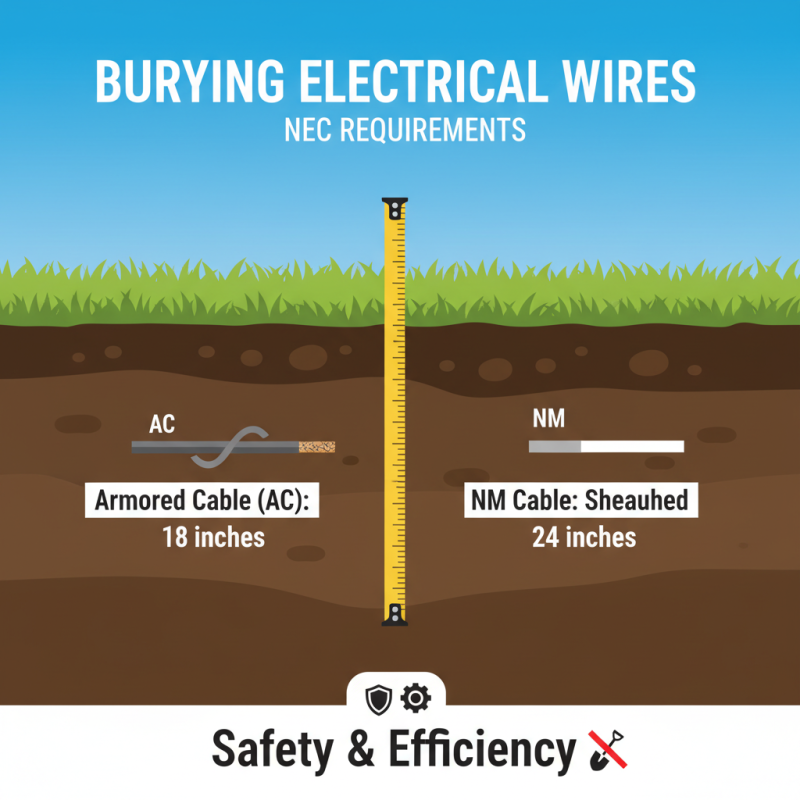

Installing underground wire safely and efficiently requires a thorough understanding of the specific requirements associated with the process. According to the National Electrical Code (NEC), when burying electrical wires, it is essential to consider factors such as the type of wire used, the depth at which it is buried, and the protections that must be in place. Typically, non-metallic sheathed cable (NM) must be buried at a minimum of 24 inches, while armored cable can be placed at a depth of 18 inches. These standards are designed to prevent accidental damage to the wiring during excavation or landscaping activities, thus ensuring long-term safety and efficiency in electrical systems.

Additionally, local regulations often dictate further specifications for underground installations. A report by the National Fire Protection Association indicates that improper installations contribute to approximately 20% of electrical fires in residential properties. To mitigate these risks, installers must also incorporate conduit protection in areas where physical damage could occur. This requirement emphasizes the importance of not only adhering to depth regulations but also understanding the environmental conditions that may affect the integrity of underground wiring. Regular inspections and adherence to these regulations can significantly enhance the performance and safety of electrical systems.

When it comes to installing underground wiring, selecting the right type of wire is crucial for ensuring safety and durability. The most common types of wire used for underground applications include UF (underground feeder) cable, which is designed to withstand moisture and direct burial, and NM (non-metallic) cable, often used in areas where it will not be exposed to extreme conditions. It's essential to consider the environment where the wire will be laid, as factors such as soil acidity, moisture levels, and the possibility of physical damage can influence your choice.

In addition to type, the wire's gauge plays a significant role in its performance. Thicker wires (lower gauge numbers) are better for longer runs as they reduce voltage drop and can handle higher current loads. Make sure to calculate the distance from the power source to the point of use to select the appropriate gauge. Furthermore, always consult local electrical codes and regulations, as these guidelines can dictate specific requirements for underground wiring, ensuring that your installation meets safety standards.

When planning the installation of underground wire, the depth and path considerations play a crucial role in ensuring both safety and efficiency. First and foremost, it’s essential to understand the local regulations regarding the minimum burial depth for different types of wiring. Typically, residential underground wiring should be buried at least 24 inches deep for non-metallic conduits and 18 inches for other types. This ensures that the wire is protected from accidental damage and provides adequate insulation from external elements.

Choosing the right path for your underground wire is equally important. Avoid routes that run close to tree roots or heavy machinery areas to minimize the risk of disruption or damage. Additionally, consider marking the path clearly to avoid future hazards during landscaping or digging projects.

Tips: Before digging, use utility locating services to ensure there are no existing underground utilities in your chosen path. This will help prevent costly accidents and service interruptions. Additionally, plan for future changes; if you anticipate additional wiring needs down the line, consider laying extra conduit during your initial installation to save time and effort later. Always double-check your measurements and local guidelines to remain compliant and ensure the longevity of your installation.

When embarking on the installation of underground wiring, proper tools and safety gear are paramount to ensure both efficiency and safety. According to the National Electrical Code (NEC), using the right equipment not only streamlines the process but also adheres to regulations that protect both the installer and the environment. Essential tools include a trenching machine or shovel for digging, a wire puller for easy installation, and a cable locator to avoid existing underground utilities. Precise measurement instruments are equally important to ensure the correct depth and distance from other utilities, which is crucial in preventing accidents and ensuring compliance.

Equipping yourself with adequate safety gear is equally important. The Bureau of Labor Statistics (BLS) highlights that electrical work, particularly involving underground wiring, poses significant risks, including electrical shocks and injuries from excavation. Wearing hard hats, gloves rated for electrical work, safety glasses, and steel-toed boots can significantly reduce the risk of injury. Additionally, utilizing high-visibility clothing increases safety, especially in busy areas. An estimated 19,000 injuries related to electrical installations occur annually in the U.S., underscoring the importance of prioritizing safety protocols during installation processes. By combining the right tools with proper safety gear, you not only safeguard yourself but also enhance the overall efficiency of the wiring installation.

When it comes to installing underground wire, ensuring safety and efficiency is essential. Start by planning your installation route, identifying any potential obstacles such as tree roots, existing utilities, and property boundaries. It's important to dig a trench that is at least 24 inches deep, as this will help protect the wire from damage and ensure that your installation complies with local regulations. Use a shovel or trenching machine for precision, making sure to keep the trench straight for easier wire laying.

Tips for a safe installation include using underground-rated wire suitable for direct burial and checking for local utility markings before you dig. Always wear appropriate safety gear, including gloves and safety glasses. Once the trench is ready, lay the wire in the bottom of the trench and cover it with a layer of sand to provide additional protection against sharp objects. It's a good idea to label the area above the buried wire so that you or others know it's there, which can prevent accidents in the future.

Before filling in the trench, take a moment to test the installation to ensure proper connectivity. After verifying everything is functioning correctly, backfill the trench carefully, pressing down the soil to avoid air pockets that could lead to settling. Following these steps will guarantee a successful underground wire installation that serves your needs safely and efficiently.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.