When it comes to sourcing wire by the foot, understanding the nuances of this industry can significantly impact both project outcomes and budgeting strategies. According to a recent report by the National Electrical Manufacturers Association (NEMA), the use of wire and cable has grown steadily over the past few years, with an expected annual growth rate of 4.1% through 2025. This underscores the rising importance of efficient material sourcing in various applications, from construction to DIY projects.

Expert in the field, John McKenzie, a renowned electrical engineering consultant, emphasizes, "Choosing the right type of wire by the foot is crucial not only for project safety but also for long-term reliability." These insights highlight the importance of factors such as wire gauge, insulation type, and length requirements. With numerous options available, it can be overwhelming to make informed decisions without a solid foundation of knowledge.

As homeowners and contractors alike seek to optimize their purchases, understanding the top things to consider when buying wire by the foot becomes essential. This guide aims to equip buyers with the necessary tools and information to navigate the complexities of their wire purchasing journey, ensuring they invest wisely in materials that meet their specific needs.

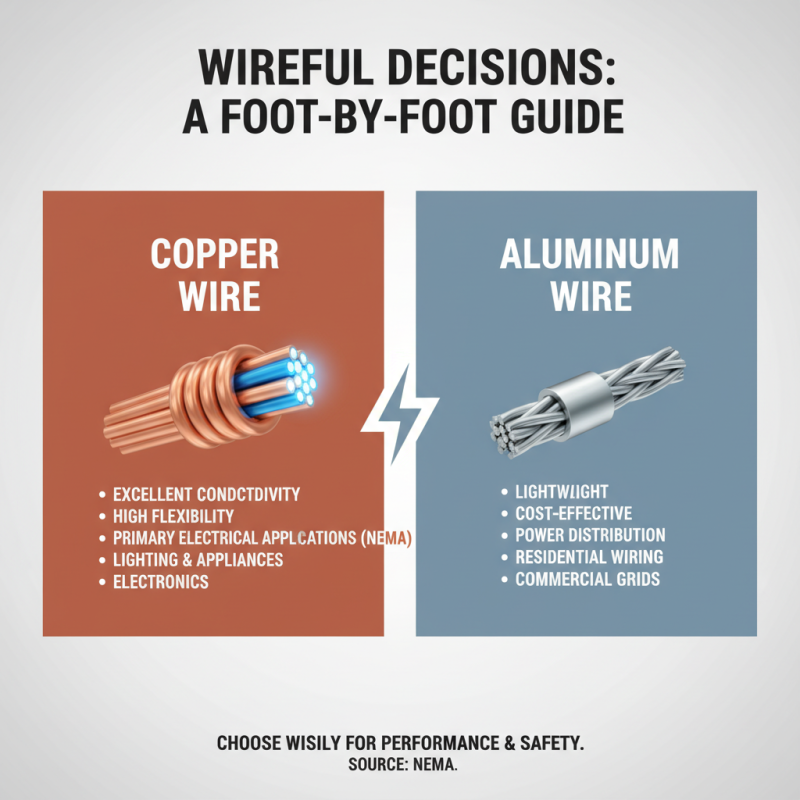

When purchasing wire by the foot, understanding the various wire types and their specific applications is essential for making informed decisions. Different wire types are designed for distinct tasks, which can significantly influence both performance and safety. For example, according to the National Electrical Manufacturers Association (NEMA), copper wire is commonly used in electrical applications due to its excellent conductivity and flexibility. On the other hand, aluminum wire, while less conductive, is often utilized in residential and commercial power distribution due to its lightweight properties and cost-effectiveness.

Furthermore, the choice of insulation type, such as PVC or Teflon, can also determine the wire's suitability for certain environments. A report from the Wire Association International indicates that specialized wires, such as high-temperature cables and those with enhanced abrasion resistance, are crucial for industries like aerospace and automotive. These wires ensure reliability in demanding conditions, where failure is not an option. As you navigate through various wire types, assessing the specific requirements of your project will lead to better performance and longevity of your installations.

When choosing wire by the foot, several key factors should be taken into consideration to ensure you select the right type for your project. First, it’s essential to understand the purpose of the wire — whether it’s for electrical applications, crafting, or other uses. Different projects require different wire characteristics, including gauge, material, and insulation type. For instance, if you need wire for outdoor use, consider a material that is resistant to weather and corrosion.

Additionally, the gauge of the wire is crucial. A lower gauge number indicates a thicker wire, which can handle more current in electrical applications or provide greater strength in crafting. It’s important to choose a gauge that meets the specific needs of your project to avoid any safety hazards or performance issues. Lastly, consider the flexibility of the wire. Some projects may require a more flexible wire for intricate designs or tight spaces, while others may need rigid wire for structural support. By assessing these factors, you can make an informed decision and select the appropriate wire by the foot for your needs.

When embarking on a project that involves wiring, calculating the amount of wire you need is crucial for both efficiency and cost-effectiveness. Start by measuring the area where the wire will be used. This includes evaluating the total length required for your specific installation, taking care to account for any turns, junctions, or connections that may increase the overall length. It is advisable to use a measuring tape to achieve accurate measurements. Additionally, consider the type of project you’re undertaking, as this may influence how much wire you will need.

Once you have your measurements, it’s beneficial to add a small buffer to your total calculation. This allows for any mistakes in cutting or unforeseen adjustments during the installation process. A common practice is to add about 10% more wire to ensure you have sufficient length to work with. Furthermore, if you're working on more complex designs, drawing out a plan can help clarify the wire’s path, making it easier to visualize and calculate the needs of your project accurately. This careful planning will help prevent delays and keep your project on track.

When seeking quality wire by the foot, determining where to make your purchase can significantly impact the experience and outcome of your project. Local hardware stores often provide convenience and instant access to a variety of wire types, allowing you to inspect the material before buying. However, the selection at brick-and-mortar locations may be limited compared to online options. Specialty electrical supply stores can also be a great resource as they often carry higher-grade materials tailored for specific applications, ensuring you find exactly what you need for your project.

For those looking to explore online options, numerous retailers offer an extensive selection of wire by the foot. Online shopping allows you to compare prices, read customer reviews, and check for certifications that guarantee quality. Additionally, e-commerce platforms often provide detailed specifications and helpful customer support that can guide your purchase decisions. Just be sure to choose reputable sellers and check return policies in case the wire doesn’t meet your expectations. Ultimately, whether you choose a physical store or an online retailer, researching the quality and suitability of the wire for your specific project is essential for achieving the best results.

When it comes to purchasing wire by the foot, understanding how to properly store and handle your wire after purchase is essential for maintaining its quality and ensuring its longevity. Proper storage not only prevents damage but also makes your work process more efficient.

One key tip is to keep your wire in a cool, dry place away from direct sunlight. Exposure to heat and moisture can cause deterioration or corrosion, particularly with certain metals. Using storage bins or organizational racks can also help keep different types of wire separated and easily accessible, reducing the risk of tangles and unnecessary waste.

Additionally, always handle wire with care to prevent kinks or bends, which can weaken its integrity. When cutting wire, use the appropriate tools to ensure clean cuts that will not compromise the wire's performance. After use, consider coiling any leftover wire neatly to avoid tangles and to save space, making it easier for your next project. These simple yet effective tips can help preserve your wire, making sure it’s ready whenever you need it.

| Dimension | Description | Storage Tips | Handling Tips |

|---|---|---|---|

| Gauge | The thickness of the wire, which affects its strength and flexibility. | Store in a cool, dry place avoid moisture. | Always handle with gloves to avoid cuts. |

| Material | Common types include copper, aluminum, and steel, each suitable for different applications. | Keep away from chemicals that might corrode the material. | Avoid twisting or bending unnecessarily to maintain its structure. |

| Length | Shipped by the foot; calculate the total length required for your project. | Keep wire coiled when not in use to prevent tangles. | Cut with appropriate tools to avoid fraying ends. |

| Coating | Some wires are coated for insulation; check compatibility with your project. | Store coated wire away from sharp objects to prevent scratches. | Inspect for any damage to the coating before use. |

| Voltage Rating | Ensure wire is rated for the electrical load required. | Keep away from direct sunlight to prevent degradation of insulation. | Do not exceed the wire's voltage rating to prevent hazards. |

| Flexibility | Some wires are more flexible for easier installation in tight spaces. | Avoid kinks or sharp bends during storage. | Use proper techniques to bend wire as needed, avoiding stresses. |

| Weight | Heavier wires may require specific handling methods. | Store heavier rolls on lower shelves to prevent accidents. | Get help if necessary when lifting heavy wire. |

| Price | Prices vary based on material type, gauge, and other factors. | Compare prices from different vendors before purchasing. | Keep receipts for warranty claims or returns. |

| Maintenance | Regular inspection helps identify issues with wire condition. | Store away from moisture to prevent rusting or corrosion. | Use protective sleeves for storage if wires must be exposed to potential damage. |

| Application | Different wires are suited for specific applications like electrical, automotive, etc. | Store wires separately by application to avoid confusion. | Follow the application guidelines for optimal performance. |

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.