In the rapidly evolving world of electrical engineering, the need for reliable and efficient electric cable wire types has never been more critical. As we approach the year 2025, understanding the various types of electric cable wire is essential for both professionals and enthusiasts alike. This comprehensive guide aims to illuminate the myriad options available, highlighting their distinctive characteristics, applications, and advantages.

Electric cable wires serve as the backbone of modern electrical systems, playing a vital role in powering homes, industries, and transportation. With advancements in technology and changing energy demands, selecting the appropriate electric cable wire can significantly impact performance, safety, and energy efficiency. By delving into this guide, readers will gain insights into the latest innovations and standards in cable wire manufacturing, ensuring they make informed decisions for their projects and installations. Whether you are working on new constructions, renovations, or simply looking to upgrade your system, understanding the types of electric cable wire available will empower you to harness the full potential of electrical energy for a sustainable future.

Electric cable wire types are essential components in modern electrical systems, facilitating the safe and efficient transfer of electricity. An understanding of these various types is crucial for both professionals in the industry and everyday consumers. The most common categories include non-metallic sheathed cables (NM), insulated power cables, and armored cables. According to the International Electrotechnical Commission (IEC), the demand for insulated cables is projected to grow at a CAGR of 8.5% through 2025, driven by advancements in infrastructure and the rising need for reliable energy solutions.

Additionally, specialty cables such as those used in renewable energy applications or high-voltage transmission play a significant role in the evolving landscape of electric wiring. Research from the United States Energy Information Administration (EIA) highlights that over 30% of new power generation capacity in the U.S. comes from wind and solar energy, necessitating specific types of cabling that can withstand unique environmental conditions. These cables are designed with enhanced insulation and durability to ensure optimal performance over their lifecycle, thereby underscoring the importance of selecting the appropriate cable type for each application.

When it comes to selecting the right electric cable wire, understanding the key characteristics of common types is essential for ensuring optimal performance and safety. For instance, copper wires are renowned for their excellent conductivity, with electrical conductivity around 59.6 x 10^6 S/m, making them the preferred choice for most electrical applications. The flexibility of copper also allows for easier installation in various settings, further enhancing its utility in residential and commercial projects.

On the other hand, aluminum wires, which are approximately 60% lighter than copper, offer a more cost-effective alternative for overhead power lines and electrical distribution systems. Although their conductivity is about 61% that of copper, advancements in alloy technologies have significantly improved their performance. According to market reports, the global aluminum wire market is expected to witness a compound annual growth rate (CAGR) of 4.3% from 2023 to 2028, driven by ongoing demand in energy and construction industries.

Additionally, specialty cables, such as those designed for high-temperature environments, possess unique characteristics such as increased insulation capabilities. These cables are critical in applications like aerospace and industrial processing, where temperature extremes can impact safety and functionality. A report by the International Electrotechnical Commission suggests that the demand for these specialty wires is projected to surpass 10% annual growth, highlighting their importance in evolving technological landscapes. Understanding these characteristics helps engineers and contractors make informed decisions tailored to specific needs and regulatory requirements.

This bar chart illustrates the key characteristics of common cable wire types based on their applications and properties in 2025. The data includes the voltage rating, flexibility, and temperature range for each type of cable wire.

When considering the various types of electric cables available, it's crucial to understand their specific applications. One of the most common types is the Non-Metallic Sheathed Cable (NM cable), which is widely used in residential wiring. Its flexible design allows for easy installation in walls and ceilings, perfect for powering outlets and light fixtures. Additionally, NM cable is ideal for indoor use, making it a staple in construction projects.

Another important category is the Armored Cable (AC), which offers enhanced protection due to its durable metal sheath. This type of cable is often utilized in industrial environments where exposure to harsh conditions is likely. The rugged construction helps prevent damage from mechanical impact, making it suitable for outdoor installations and areas that require additional safety measures.

Similarly, the Power Cable plays an essential role in transmitting electricity over long distances. These cables are designed for high voltage applications, supplying power to residential, commercial, and industrial facilities. Their robust design ensures minimal energy loss during transmission, making them a vital component of the electrical infrastructure. Each type of cable has its unique benefits, and selecting the right one depends on the specific needs of the application at hand.

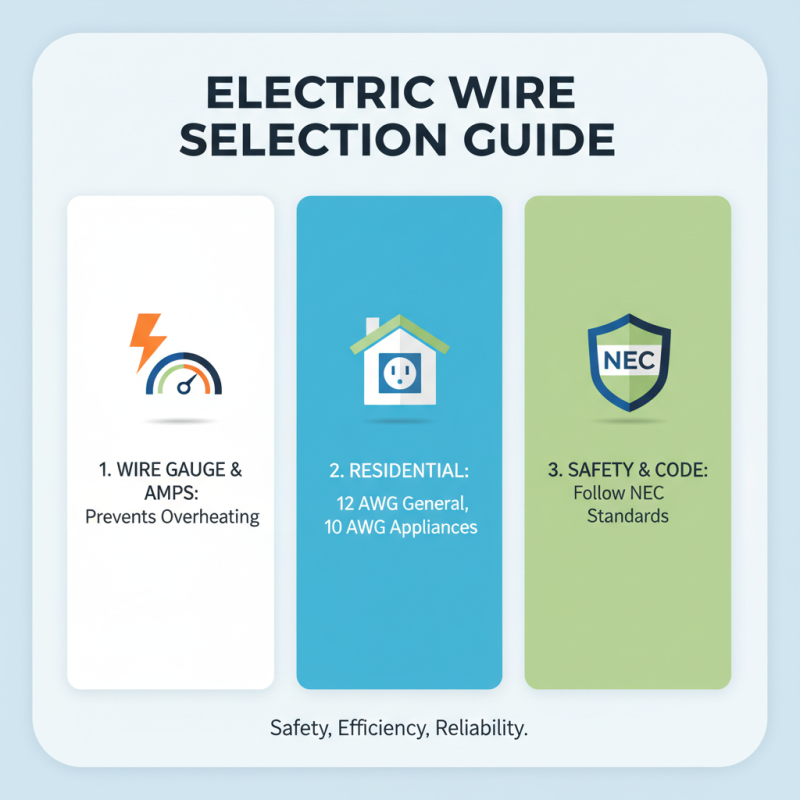

When selecting electric wires for various applications, several critical factors must be taken into account to ensure safety, efficiency, and reliability. One of the primary considerations is the wire's gauge, which determines the amount of current that the wire can safely carry. According to industry reports, a wire’s gauge affects its resistance and heat generation; thus, choosing the right size is vital to prevent overheating and potential hazards. For residential wiring, the National Electrical Code (NEC) recommends a minimum of 12 AWG for general circuits, while larger appliances may necessitate 10 AWG or even thicker wires.

Another essential factor is the wire insulation type, which varies depending on the environment the wire will be exposed to. For instance, PVC insulation is suitable for indoor applications, while thermoplastic rubber (TPR) offers better flexibility and durability for outdoor use. In harsh environments, wires may need to be rated for moisture resistance and chemical exposure. Industry statistics show that improperly chosen insulation can lead to failures and short circuits, making it crucial to understand the specific application requirements.

**Tips:** Always verify the wire’s voltage rating alongside the insulation type to ensure compatibility with the application requirements. Additionally, consider the temperature rating of the insulation, especially in areas prone to extreme temperatures. Ensuring the wire is rated for the conditions it will face is essential for long-term performance.

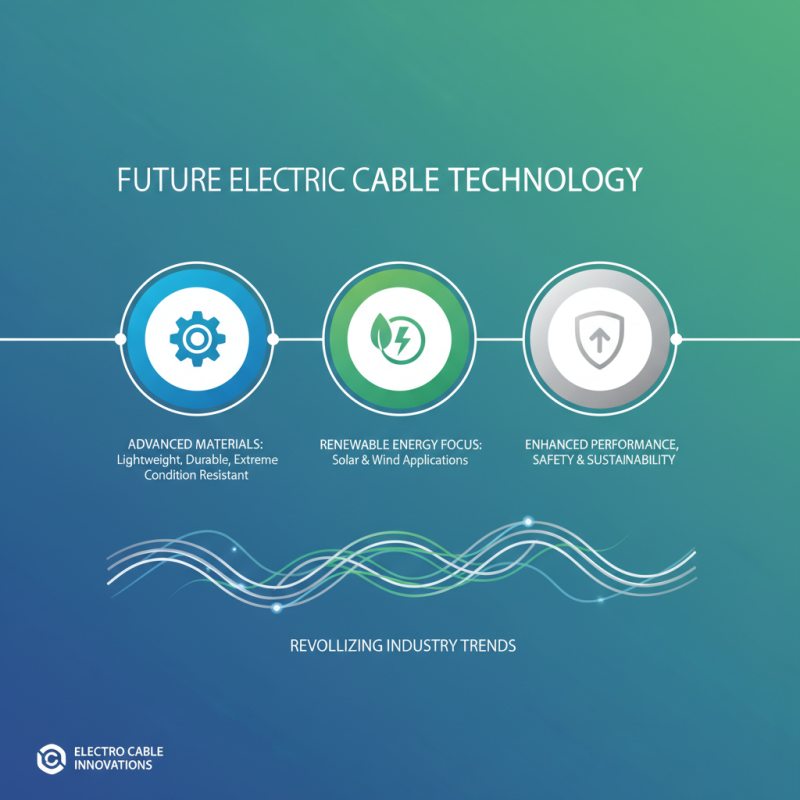

As we look towards the future of electric cable technology, several emerging trends are set to revolutionize the industry by enhancing performance, safety, and sustainability. One notable trend is the increasing use of advanced materials, such as insulated thermoplastics and innovative composites, which are not only lightweight but also provide greater durability and resistance to environmental factors. These materials allow cables to function efficiently in extreme conditions, making them ideal for renewable energy applications, including solar and wind installations.

Another significant development is the push for greater energy efficiency and reduced environmental impact. Cable manufacturers are focusing on designs that minimize energy loss and promote recycling, aligning with global sustainability goals. Smart cables equipped with sensors are also gaining traction, as they can monitor performance in real time, detect faults, and enhance maintenance routines. This integration of technology not only improves reliability but also contributes to smarter energy management systems. As electric cable technology evolves, these trends will shape the way we harness and transmit energy, paving the way for a more sustainable future.

At Radix, we do more than sell products; we provide solutions. We take the time to learn about each customer and your unique challenges, and then our knowledgeable team of problem solvers works to educate you on the possibilities to improve your products or operations.

From cutting-edge technology applications to extreme industrial environments, we’re here to collaborate, innovate, and elevate your success. Let’s connect.